From Factory to Poland – Shipping the Upgraded HE1704 CNC Press Brake

Release Time:

Jun 27,2025

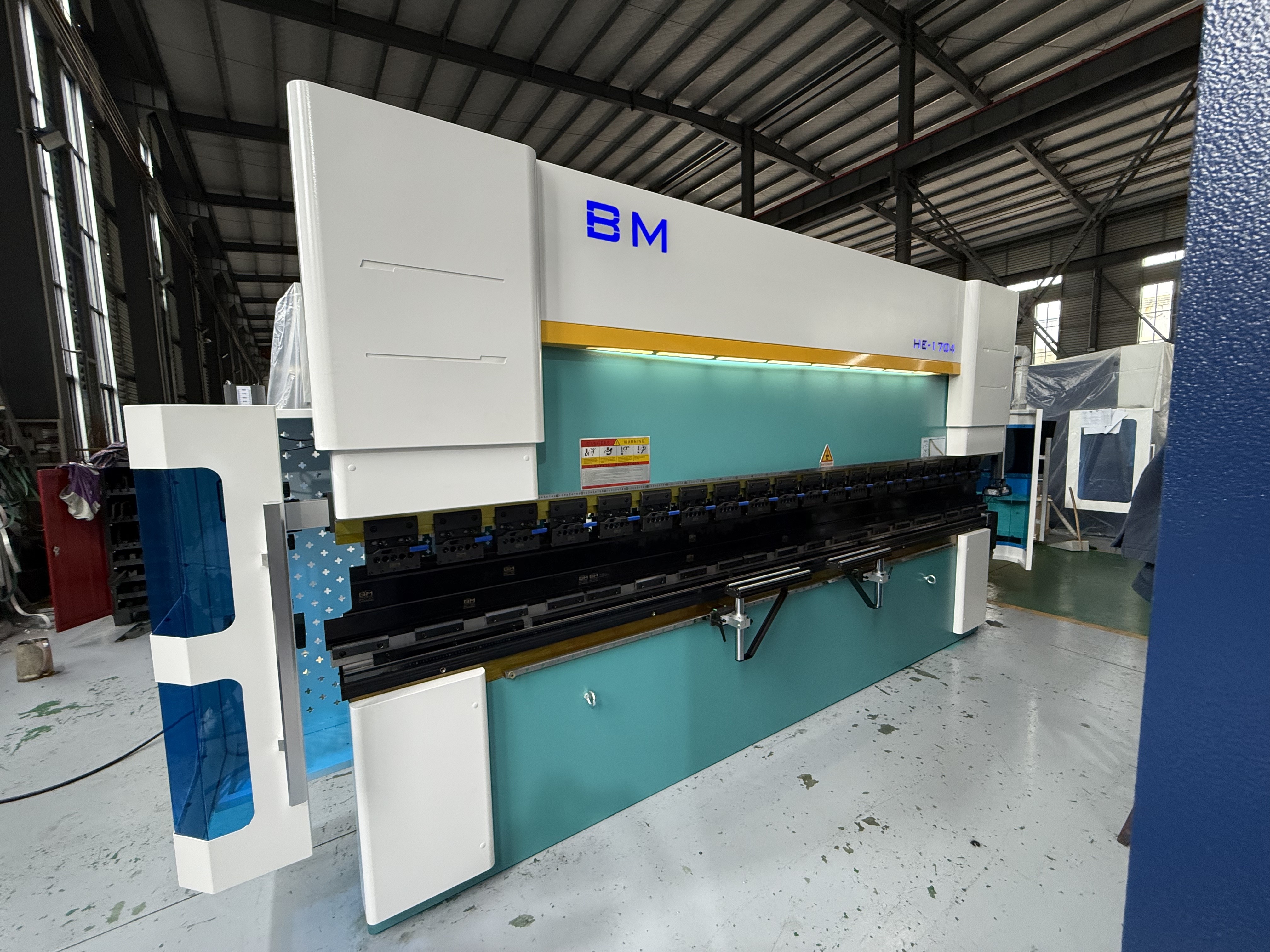

At BM Machinery, every shipment tells a story — not just of a product, but of precision engineering, customization, and a promise of quality that crosses borders. This month, we’re excited to share the successful dispatch of our flagship press brake model HE1704 to Poland.

BMpressbrake is going out.

Destination: Poland

Address: Bugajska 41, Kostomłoty Drugie, Poland

The model shipped:

HE1704 CNC Hydraulic-Electric Servo Press Brake, 8+1 Axis configuration, DELEM DA-69S control system (latest upgrade).

The HE1704 is one of BM’s most advanced machines to date, combining power, intelligence, and reliability. It’s part of the HE Series, which represents the next generation of CNC press brakes built for heavy-duty, high-precision metal fabrication.

Technical Highlights:

Specification | Details |

Tonnage | 170 Tons |

Bending Length | 4.2 Meters (4200mm) |

Axes Configuration | Y1, Y2, X, R, Z1, Z2, V + 1 compensation |

Control System | DELEM DA-69S CNC Controller |

Main Motor | 18KW Servo Motor |

Backgauge System | Dual linear guides with ball screw drive |

Crowning | CNC Mechanical Crowning System |

Lighting | LED Light Strips (Enhanced Visibility) |

Built with Durability in Mind

To ensure long-term reliability and accuracy, the HE1704 features a heavy-duty frame with key components constructed using thickened materials:

- Frame Wall Plates, Slide, and Worktable Sides: 70×70×90cm

- Grating Ruler: Ensures precise position feedback

- Oil Cylinder & Pump System: For stable and consistent bending pressure

- High-Response Servo Valves: For fast, accurate ram movement

- Laser Safety Device & Rear Safety Door: For operator protection

Every HE1704 unit is also customized based on customer requirements, including upper punches, 4-V lower dies, and specialized die bases.

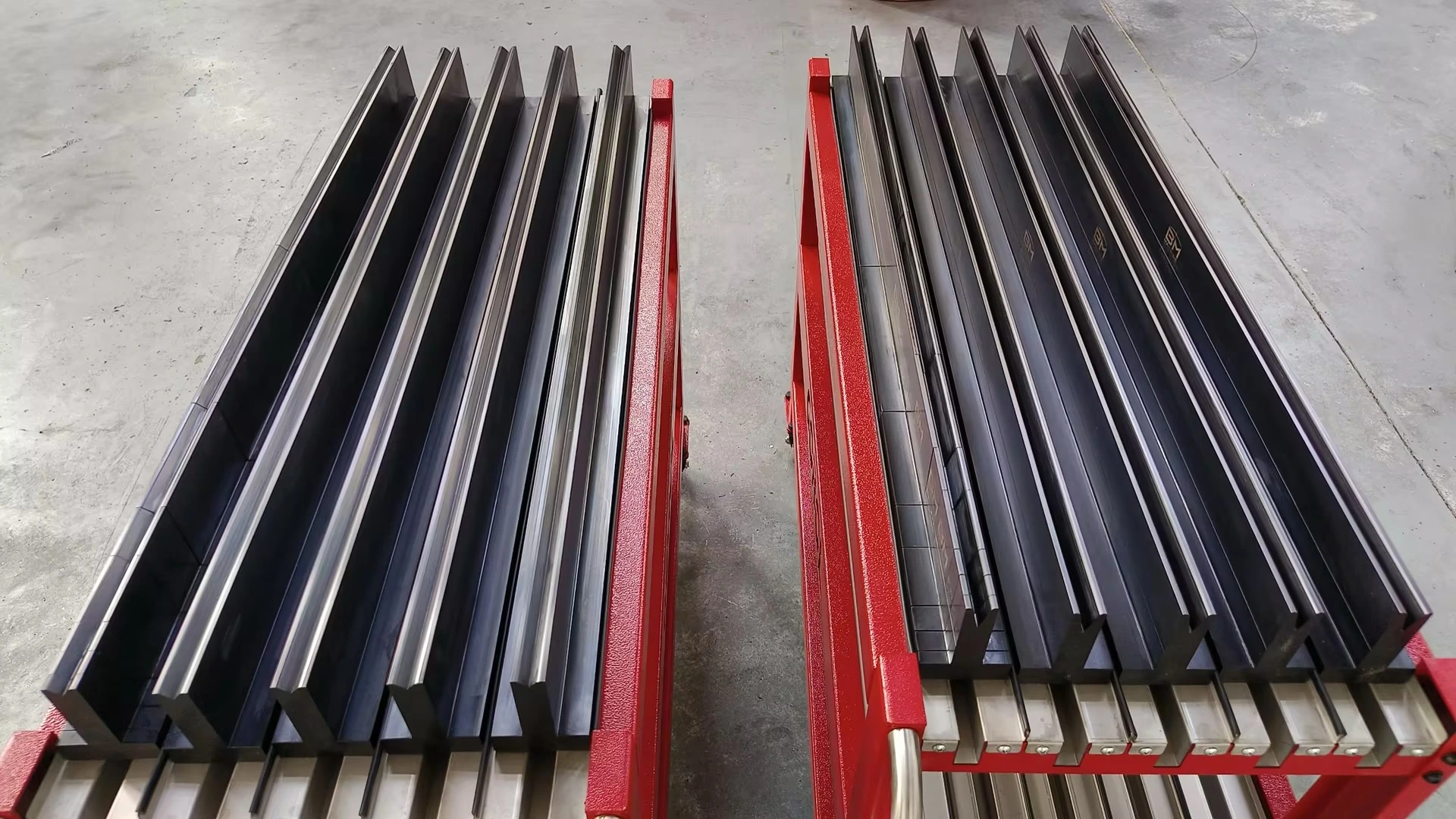

About the Bending Tools

Along with the press brake, our customer in Poland ordered 100 quick-change clamps, which are:

- Compatible with BM’s entire range of upper tools

- Designed for fast tool changes

- Built with the latest dual-sided clamping system

- Heat-treated for long life and heavy usage

This set of clamps gives the operator unmatched efficiency when switching between different tooling setups, especially in small-batch or flexible production environments.

Packing & Transport – Safe and Professional

Shipping a large CNC machine across continents requires expertise — not just in packaging, but in planning every step of the journey.

Here’s how BM ensures secure and damage-free delivery:

- Anti-Rust Coating & Moisture-Proof Wrapping

- Clear Labeling & Export Documentation

- Logistics Coordination

What’s Next?

This is just one of many HE Series machines heading to Europe this year. As more manufacturers demand smart, powerful, and flexible bending solutions, BM is responding with machines that not only perform — but also ship safely and arrive ready to work.

We thank our Polish partners for their trust and collaboration, and we look forward to seeing the HE1704 in action soon!

Want to See More?

We’ll be sharing more photos and video updates as the HE1704 arrives and gets installed in Poland.

📬 If you’re interested in BMpressbrake &bmtooling or want to inquire about pricing, shipping, or technical specs, feel free to reach out:

📧 info@brm-laser.com

🌐 www.brm-laser.com

📞 WhatsApp / WeChat: 86 18867408079

Language

Language