Electric Hydraulic Servo CNC Press Brake

Product Video

Advantage

CNC Controls

DELEM - DA53T

✔ "Hot-key” touch navigation

✔ 10.1" high resolution colour TFT

✔ Up to 4 axes (Y1,Y2 + 2 aux. axes)

✔ Crowning control

✔ Tool / material / product library

✔ Servo and frequency inverter control

✔ Advanced Y-axis control algorithms for closed-loop as well as open-loop valves

✔ TandemLink (option)

✔ USB memory stick interfacing

✔ Profile-T offline software

CNC Controls

CYBELEC - CT12

✔ 12’’ high-definition display touch screen, icon recognition function

✔ Easybend page is very convenient for single-step bending

✔ Various automatic calculation functions for bending steps

✔ Efficient bending programming meets batch multi-step bending requirements

✔ Automatically calculate bending angle, main pressure and deflection

✔ Automatic calculation of bending data, pressure, deflection compensation and punch depth

✔ Angle, backgauge correction, 2D graphics programming

✔ Automatically simulate bending steps to provide optimal bending solutions

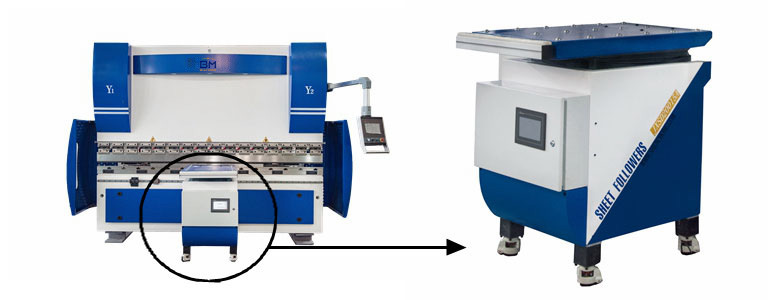

Trolley type follow-up front support - SDC3060

|

No. |

details |

|

parameter |

remarks |

|

1 |

Lifting weight |

Kg |

300 |

|

|

2 |

Lifting Angle |

degree |

60 |

Lift Angle is calculated by bending Angle |

|

3 |

Working table length |

mm |

1000 |

|

|

4 |

Length extension |

mm |

2300 |

|

|

5 |

Table width |

mm |

770 |

|

|

6 |

Height control |

mm |

100 |

Hand lift |

|

7 |

Turnover accuracy |

degree |

±0.3 |

|

|

8 |

Table height |

mm |

960-1060 |

|

|

9 |

Motor power |

KW |

4.4 |

|

|

10 |

Machine weight |

Kg |

About 700 |

|

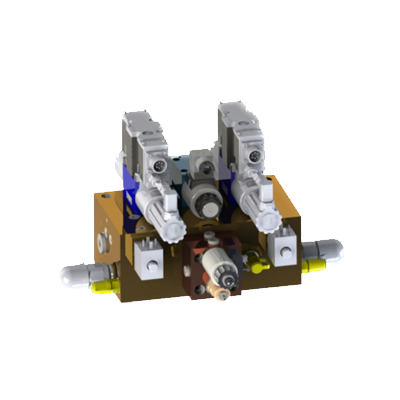

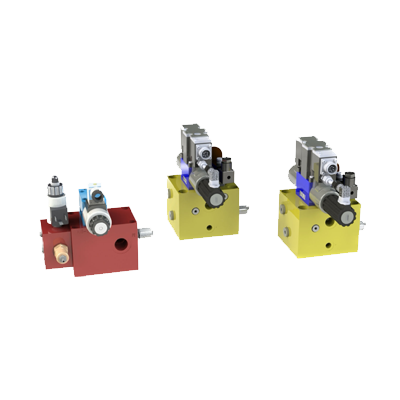

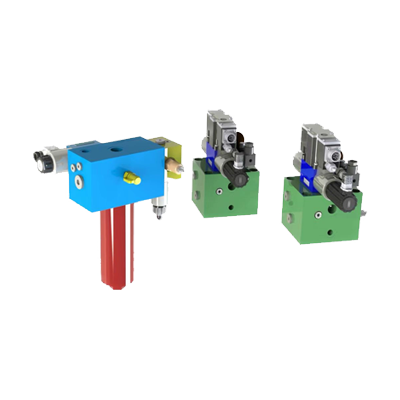

Valve- from Germany Rexroth

✔ Rexroth high response proportional valve NG06

✔ Less service expenses and easy to be maintained

✔ Repeat position accuracy is +/-0.01mm

✔ SFE/PV prefill valve, Pipeline high pressure filter

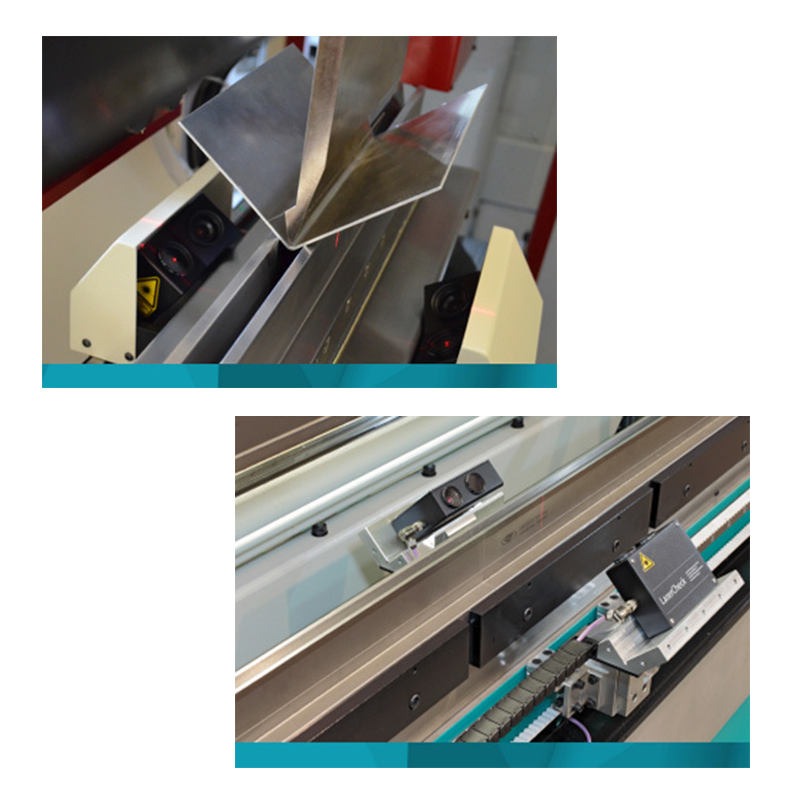

LaserCheck - Bending Angle Measurement System

✔ High-tech products “Made in Germany”

✔ Parallel use of 2 or 4 sensors

✔ Connection to ESA, Cybelec, Delem, Amada and Robosoff controls

✔ Integrated OEM solutions for ESA, Amada, Robosoff and others

✔ Bending angles from 80 to 160° with a precision of +/- 20'

Sample

Application Industry

Technical Parameter

| Specifications | Model | ||||||||

| HE1103 | HE1104 | HE1703 | HE1704 | HE2203 | HE2204 | HE8025 | HE5015 | ||

|

Bending force |

KN | 1100 | 1100 | 1700 | 1700 | 2200 | 2200 | 800 | 500 |

|

Table length |

MM | 3200 | 4100 | 3200 | 4100 | 3200 | 4100 | 2500 | 1500 |

|

Table height |

MM | 900 | 900 | 900 | 900 | 950 | 950 | 900 | 900 |

|

Column spacing |

MM | 2500 | 3480 | 2500 | 3480 | 2600 | 3600 | 2000 | 1280 |

|

Throat depth |

MM | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 250 |

|

Slider stroke |

MM | 200 | 200 | 200 | 200 | 250 | 250 | 160 | 160 |

|

Maximum opening height |

MM | 470 | 470 | 470 | 470 | 470 | 470 | 470 | 470 |

|

Approach speed |

MM/S | 200 | 200 | 160 | 160 | 150 | 150 | 200 | 180 |

|

Return speed |

MM/S | 160 | 160 | 160 | 160 | 110 | 110 | 170 | 180 |

|

Working speed |

MM/S | 13 | 13 | 10 | 10 | 10 | 10 | 12 | 15 |

|

X-axis stroke |

MM | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 |

|

X-axis maximum operating speed |

MM/S | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

|

X-axis positioning accuracy |

MM | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

|

X-axis repeat positioning accuracy |

MM | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

|

Y-axis positioning accuracy |

MM | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

|

Y-axis repeat positioning accuracy |

MM | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm |

|

R-axis stroke |

MM | 150mm | 150mm | 150mm | 150mm | 150mm | 150mm | 150mm | 150mm |

|

R-Axis Maximum Operating Speed |

MM/S | 100mm/s | 100mm/s | 100mm/s | 100mm/s | 100mm/s | 100mm/s | 100mm/s | 100mm/s |

|

Working precision |

MM |

Straight line:±0.2mm/m Angle:±0.5°/m |

Straight line:±0.2mm/m Angle:±0.5°/m |

Straight line:±0.2mm/m Angle:±0.5°/m |

Straight line:±0.2mm/m Angle:±0.5°/m |

Straight line:±0.2mm/m Angle:±0.5°/m |

Straight line:±0.2mm/m Angle:±0.5°/m |

Straight line:±0.2mm/m Angle:±0.5°/m |

Straight line:±0.2mm/m Angle:±0.5°/m |

|

NC Number of Axes |

4+1Axis | 4+1Axis | 4+1Axis | 4+1Axis | 4+1Axis | 4+1Axis | 4+1Axis | 4+1Axis | |

|

Main motor power |

KW | 7.5KW | 7.5KW | 17.8KW | 17.8KW | 22KW | 22KW | 5.5KW | 5.5KW |

|

oil tank volume |

L | 200L | 200L | 200L | 200L | 350L | 350L | 170L | 170L |

|

Outline dimension |

4000*1750*2450 | 5100*1750*2450 | 4000*1750*2450 | 5100*1750*2450 | 4100*1850*2960 | 5100*1850*2960 | 3200*1600*2450 | 2000*1600*2450 | |

|

Machine weight |

KG | 8500 | 11000 | 10000 | 12000 | 14000 | 15000 | 7500 | 6500 |

|

Oil pump displacement |

CC | 16 | 16 | 25 | 25 | 32 | 32 | 10 | 10 |

|

Rated pressure |

KG | 280 | 280 | 280 | 280 | 280 | 280 | 280 | 280 |

|

Maximum pressure |

KG | 290 | 290 | 290 | 290 | 290 | 290 | 290 | 290 |

Configuration Sheet

Have Questions? Talk to Our Experts!

Related Products