Oil-electric Hybrid Bending Machine

Product Video

Advantage

Switzerland (CYBELEC) CybTouch 12G Control System /

CybTouch 12 G

- Very simple to use with intuitive touch screen programming

- Higher quality and productivity increase

- Powerful features for maximum outpu

- Automatic calculations of the shear functions according to material specifications.

- Large cutting sequences and programs can be memorized.

- Easy communication via wireless connection to a laptop computer.

- Over 10 languages available.

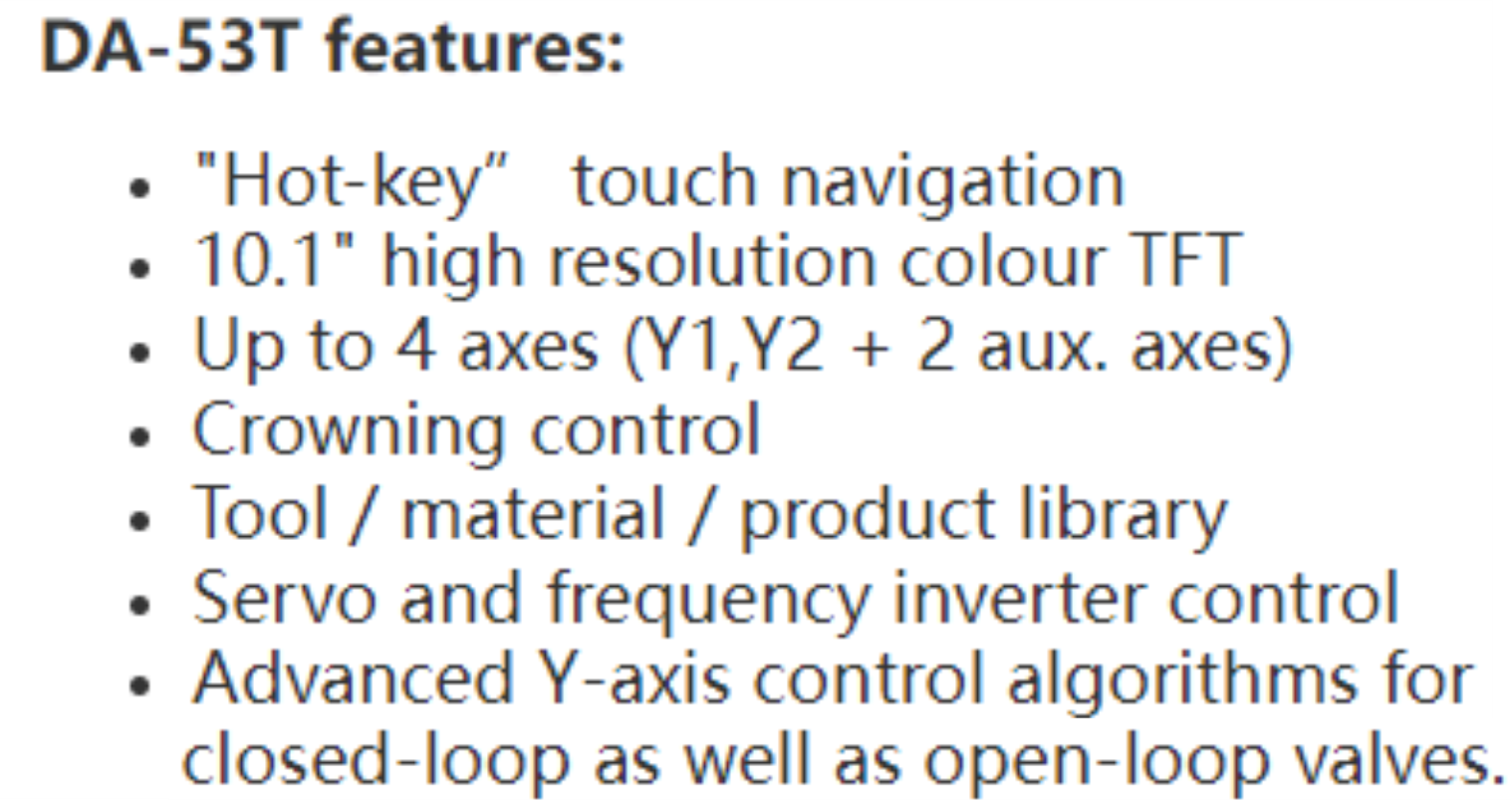

DA-53T features:

- "Hot-key” touch navigation

- 10.1" high resolution colour TFT

- Up to 4 axes (Y1,Y2 + 2 aux. axes)

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

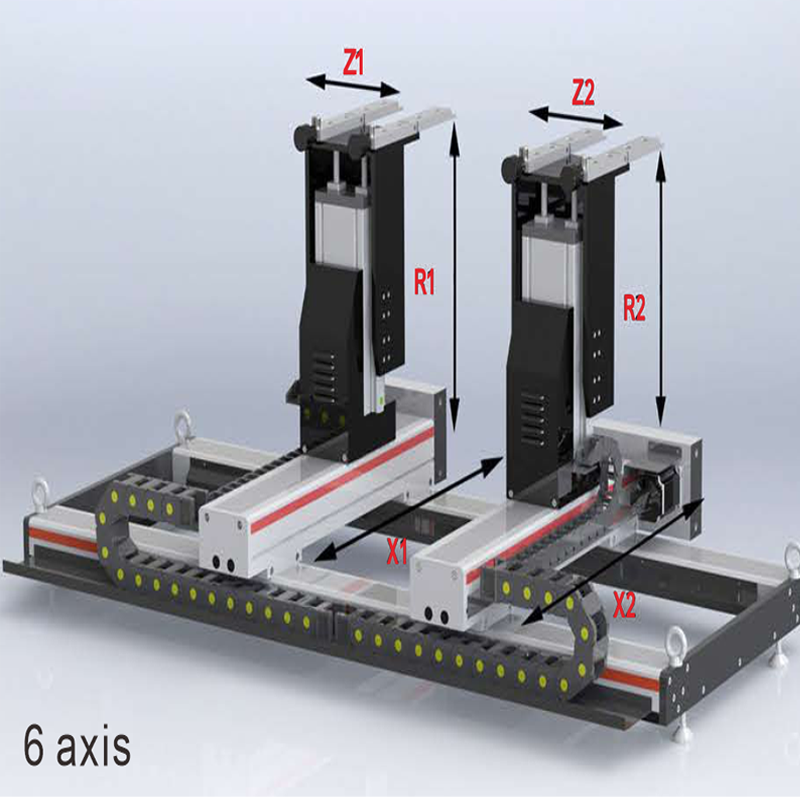

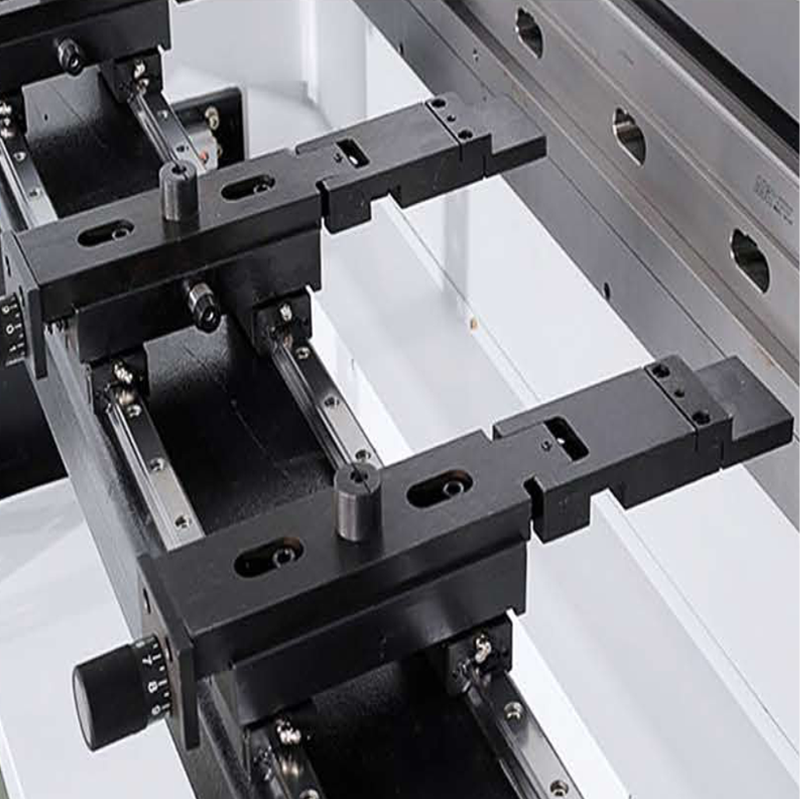

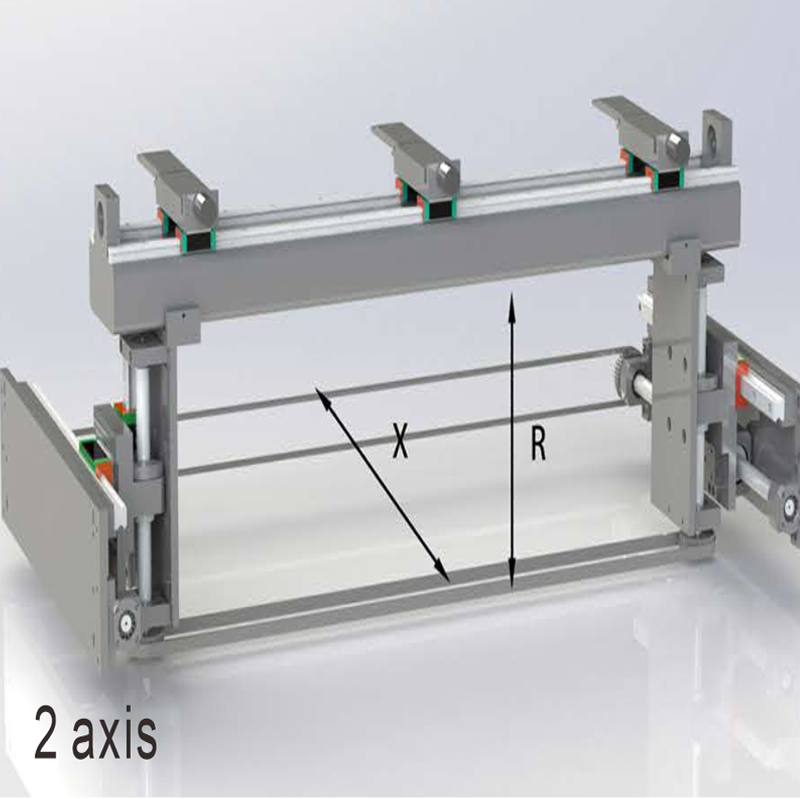

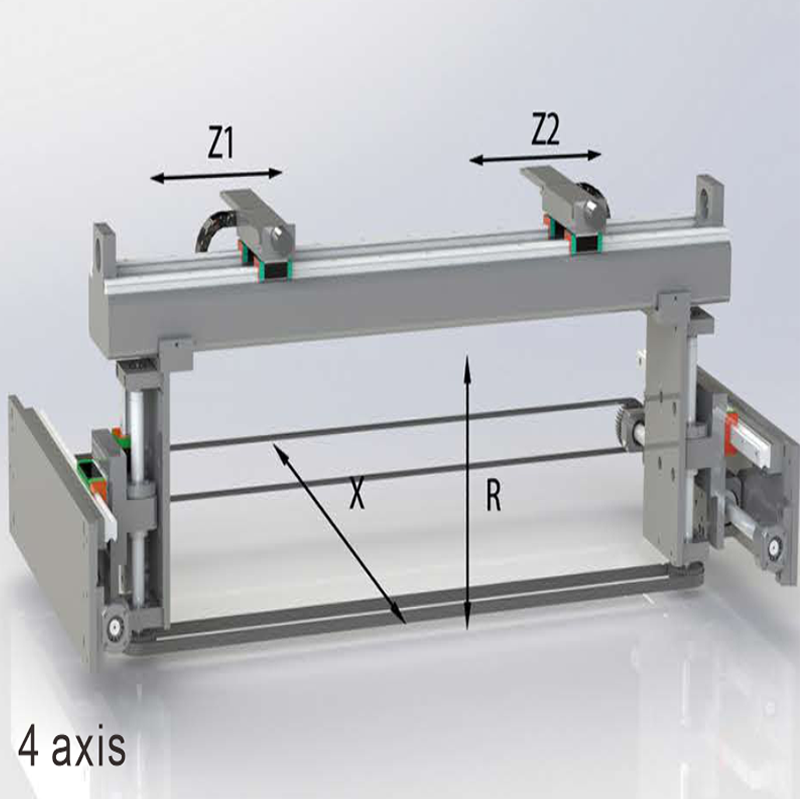

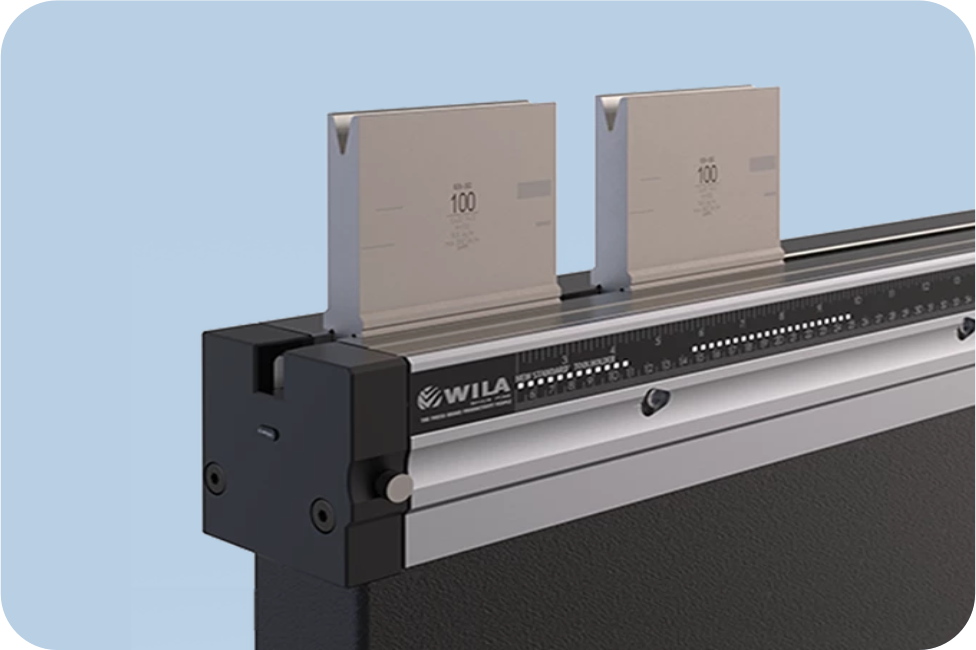

Backgauges

Available in four different types, from 4 to 9 axis, for maximum production flexibility. Each backgauge comprises an extremely rigid ram. All axes slide on linear guides to guarantee accuracy and sturdiness.

1. Front sliding shelves / 2. Mechanical Servo Bending Help (Option)

1. Pair of front sliding shelves with capacity of 120 kg that support the sheet of metal being machined. They guarantee ergonomic use and ease of handling for the workpieces.

2. The sheet support of the bending help can follow up the sheet when it is in the bending process. The followup angle and speed are automatically calculated and controlled by CNC. Bending help can be moved along the linear guide

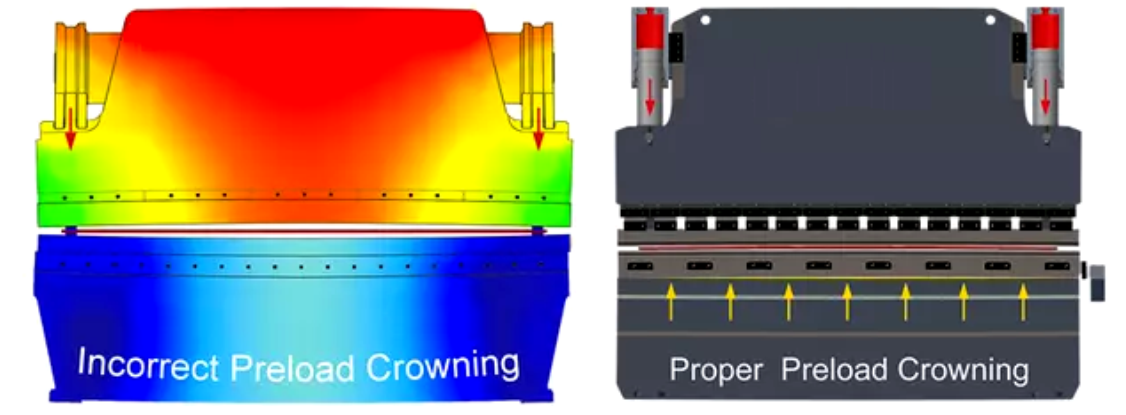

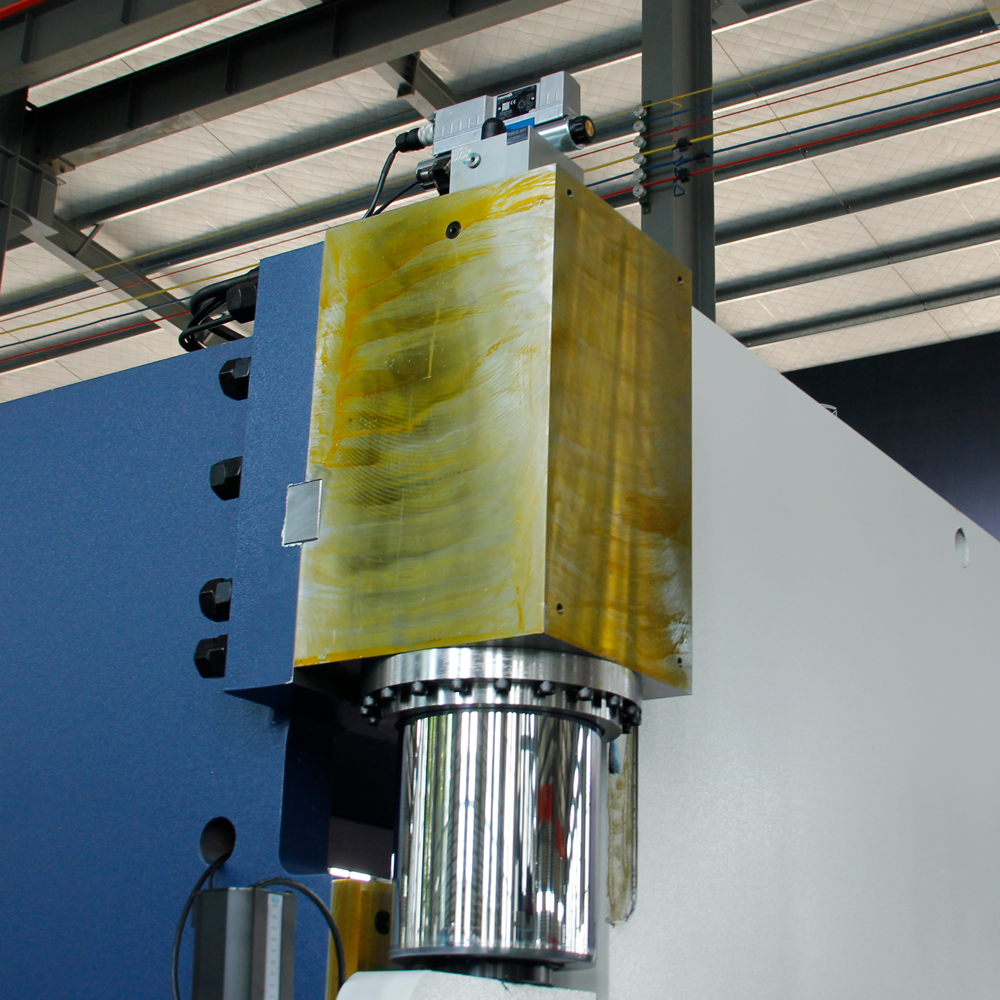

Automatic Compensation System for Mechanical Deflection

* Compensate the bending station laterally and vertically

* Calculate compensation based on length, thickness and angle of bending workpiece

* Take accurate control of compensation precision as a result of a high-precision potentiometer

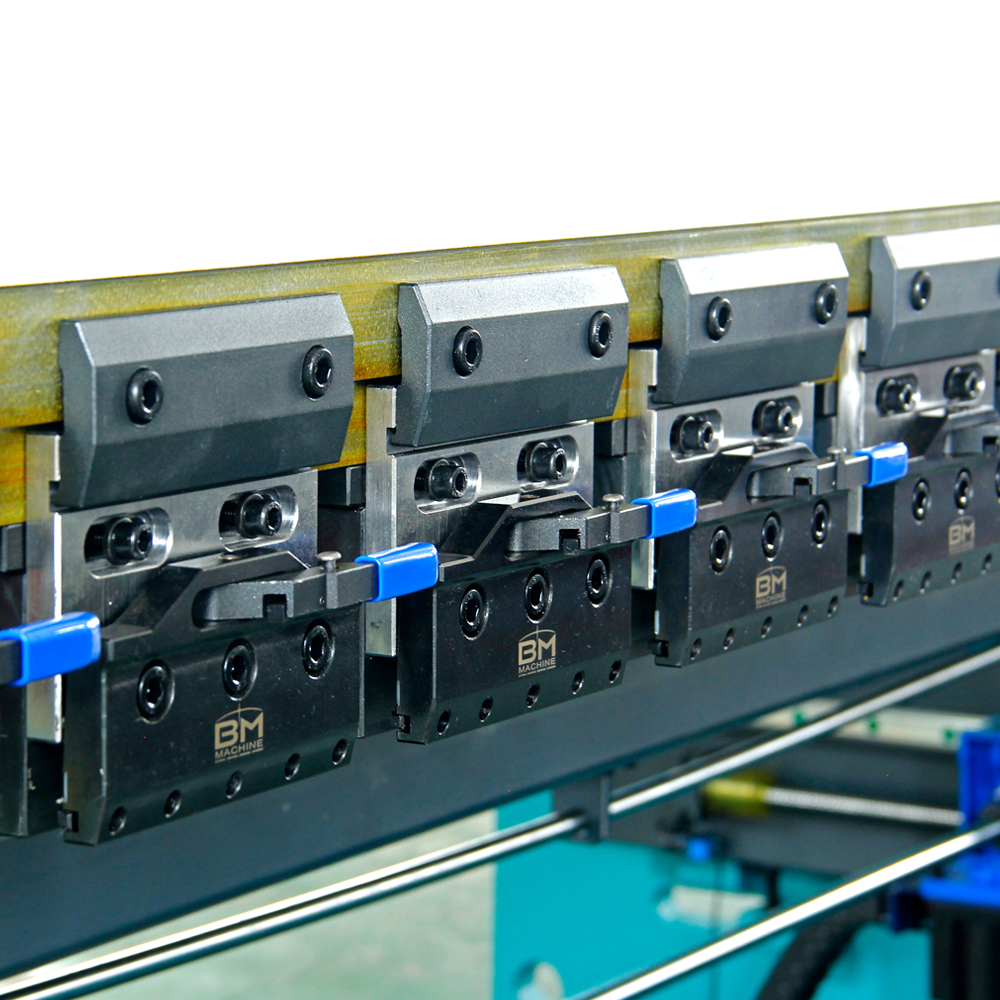

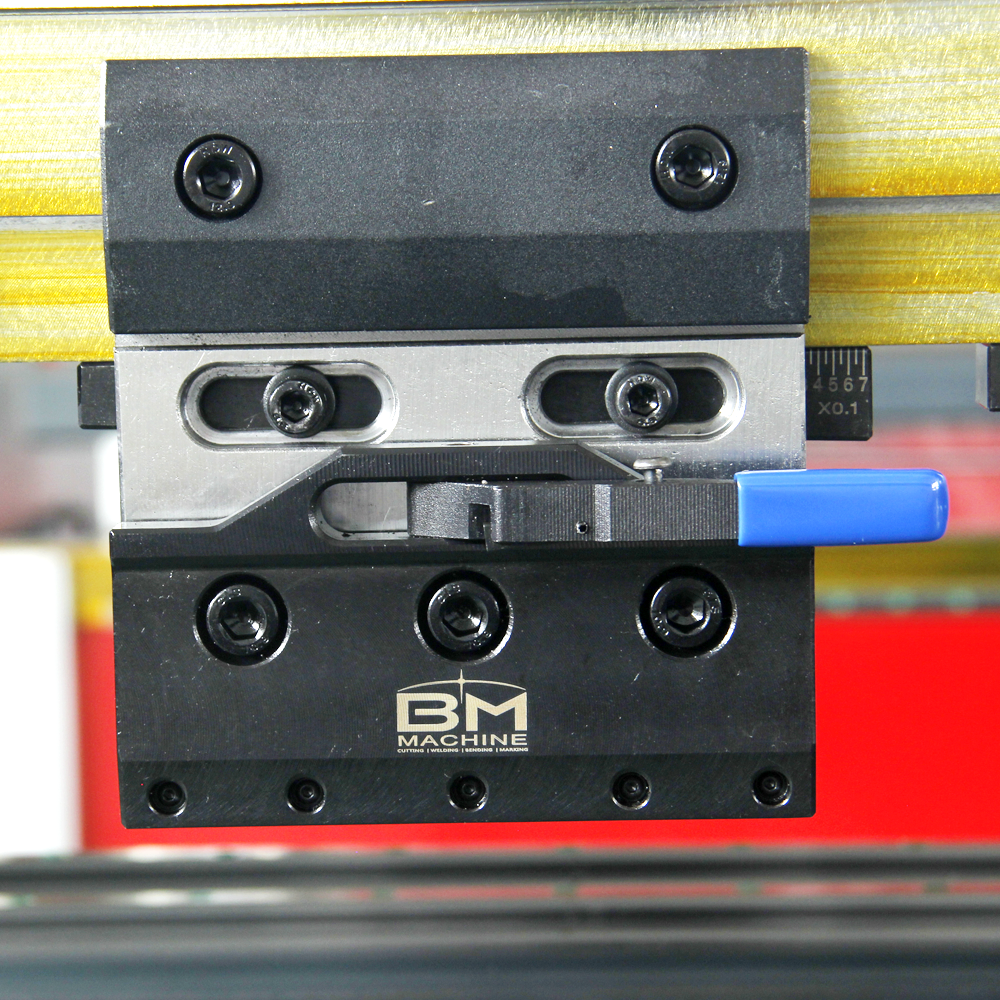

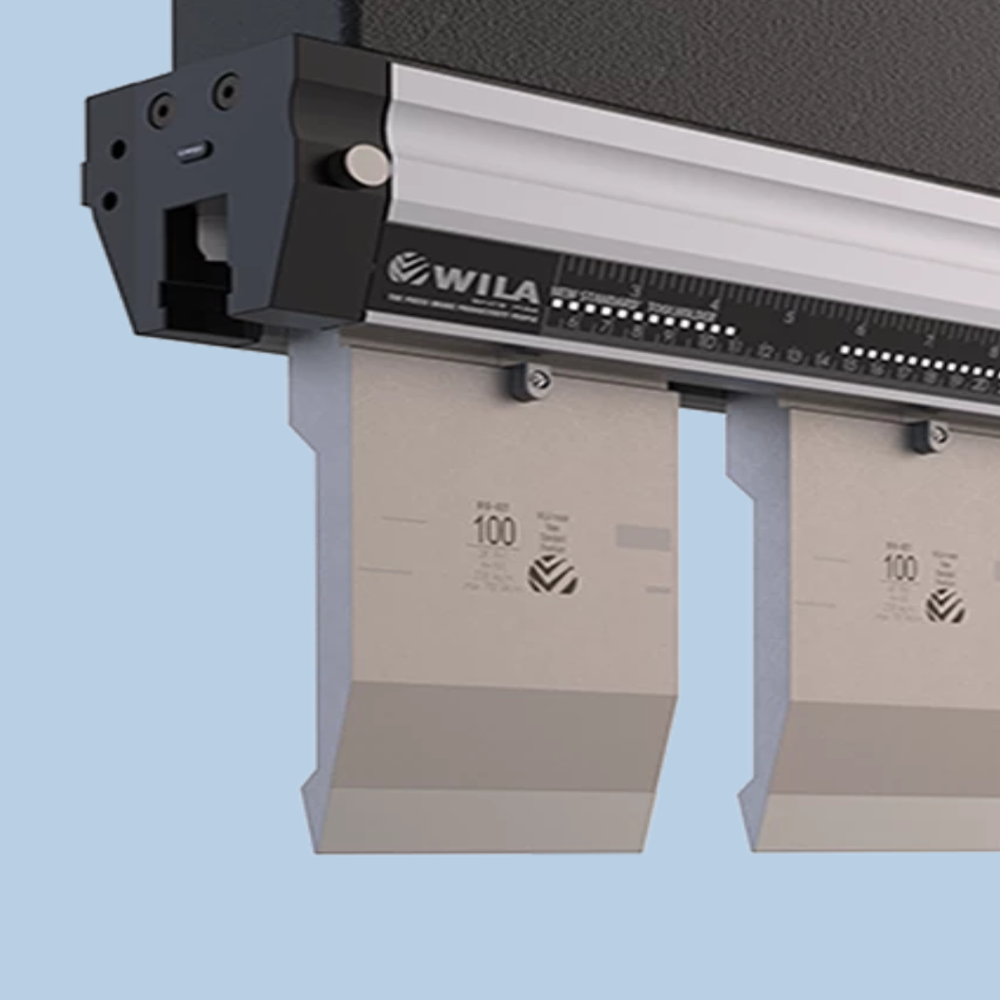

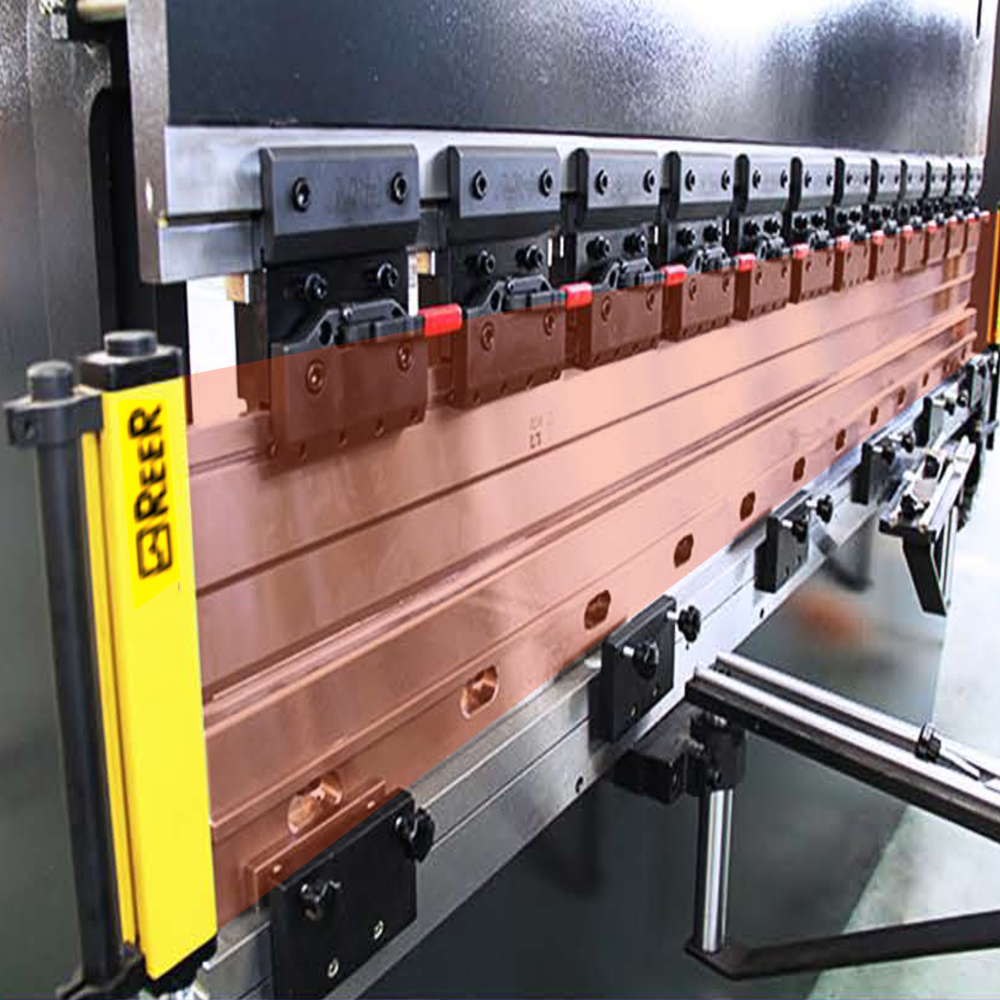

One-key Release Fast Clamp

The one-key release fast clamp could ensure the safe and fast punch changing, with strict quality requirements and procurement standards of raw materials, which keeps the punch from falling out.

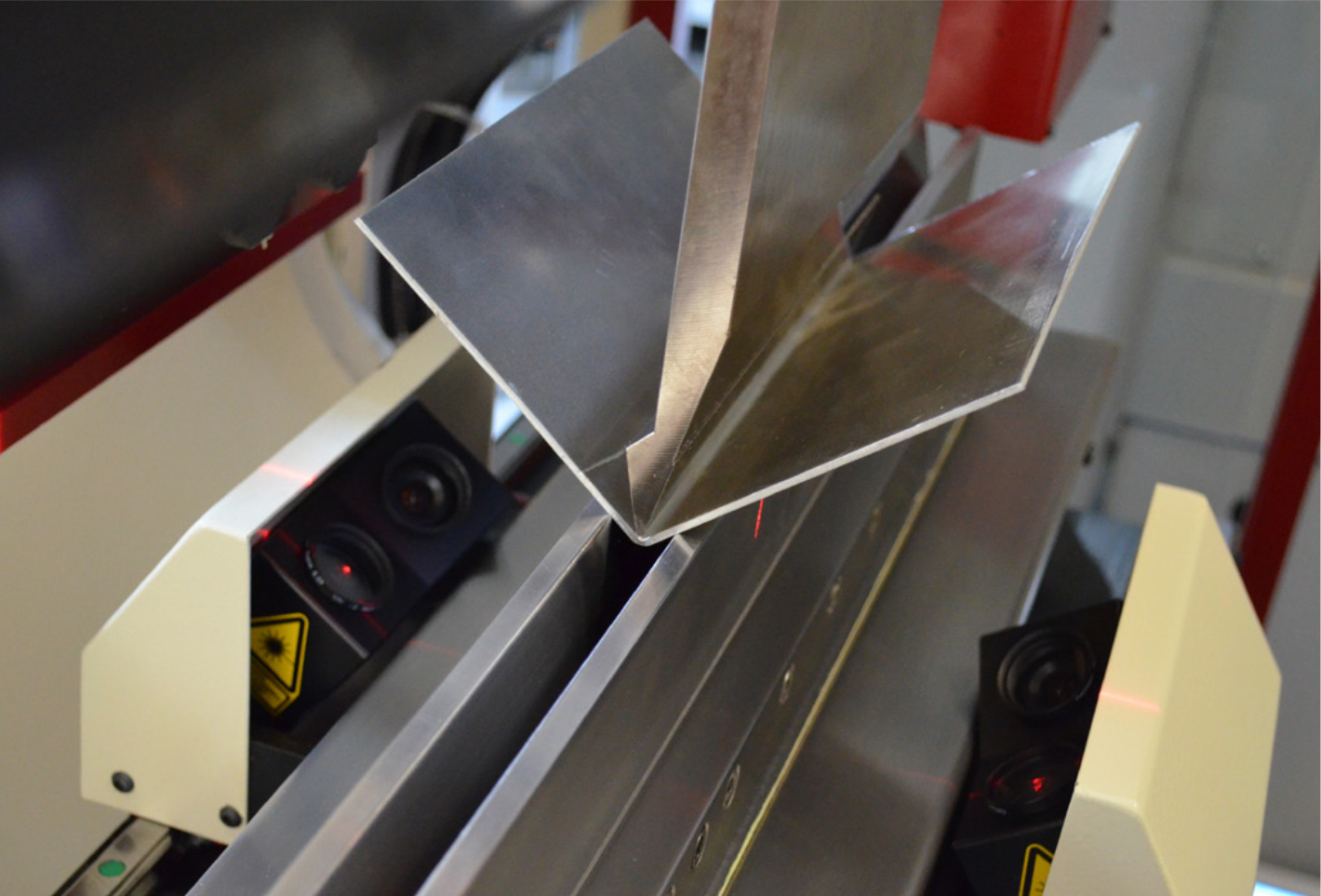

1. Laser Protection (optional) / 2. Safety Light Curtain (optional)

1. The DSP laser protection with 3 modes comprehensively protects the personal safety of the operators and maintains the high level of the productivity of the BM press brake.

2. The light curtain, BM chooses is from the well-known brands, with perfect performance to offer a highly effective solution for both operator safety and machine productivity.

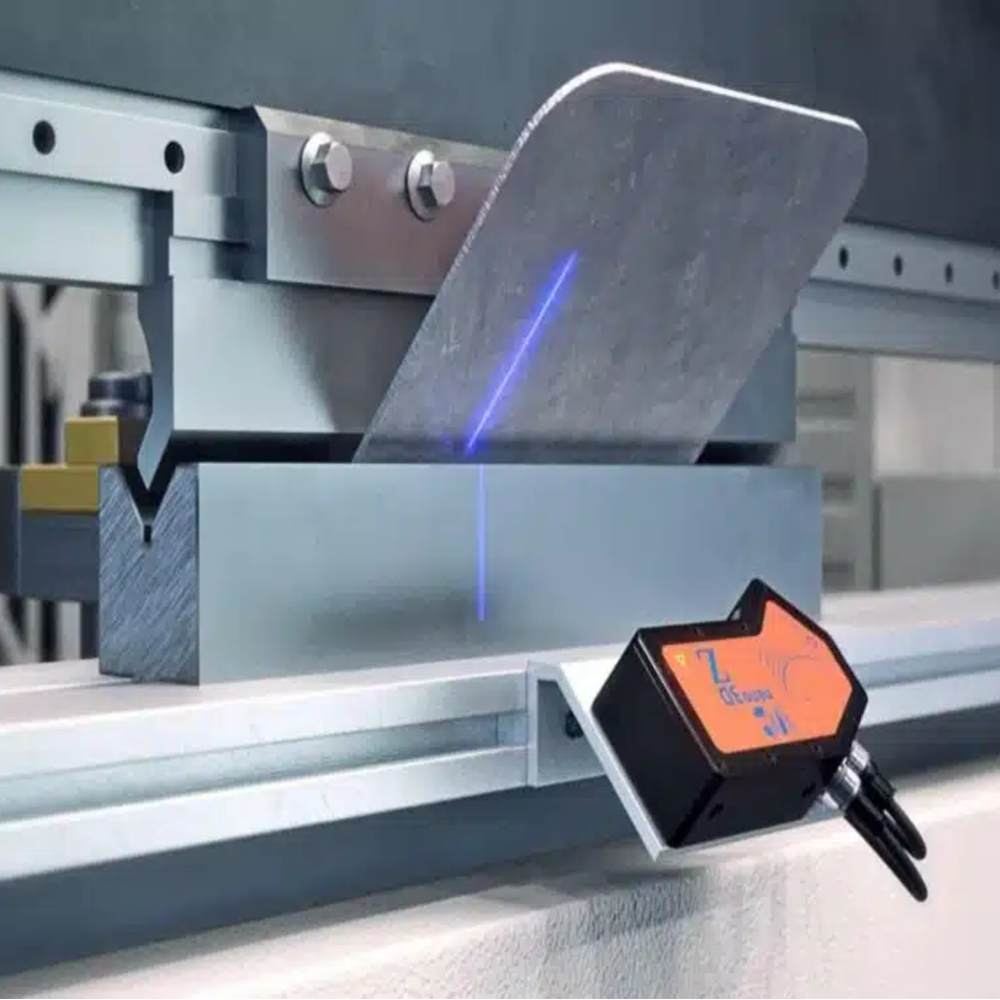

Bending Angle Measurement System (optional)

1. Laser-based Bending Angle Measurement System

2. Innovative sensors for measuring bending angles on press brakes

3. High-tech products “Made in Germany”,Very high accuracy

1. Hydraulic Clamping (Option) / 2. 1-V Automatic Hydraulic Clamping (Option)

1. Clamping and loosing actions are electrically controlled. Strong clamping force, easy and effective change of tool.

2. Clamping and loosing actions are electrically controlled, easy and effective change of lower die

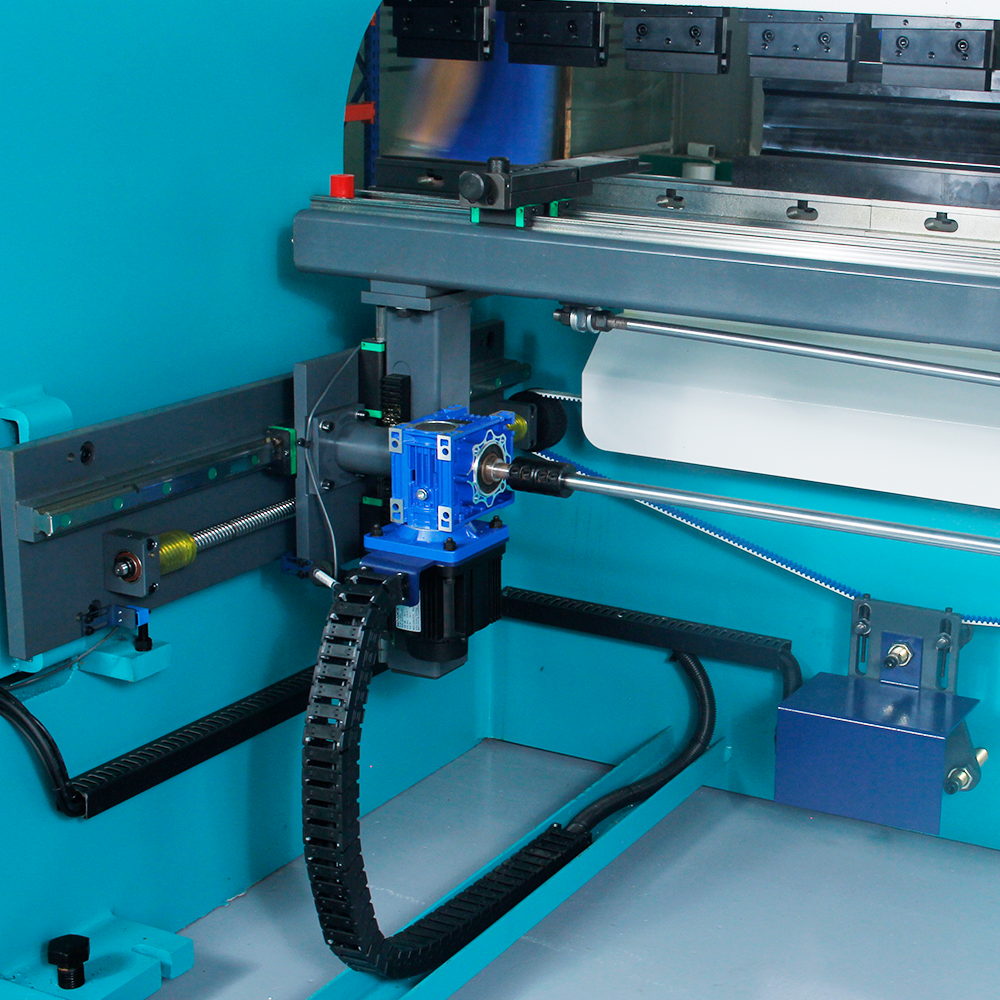

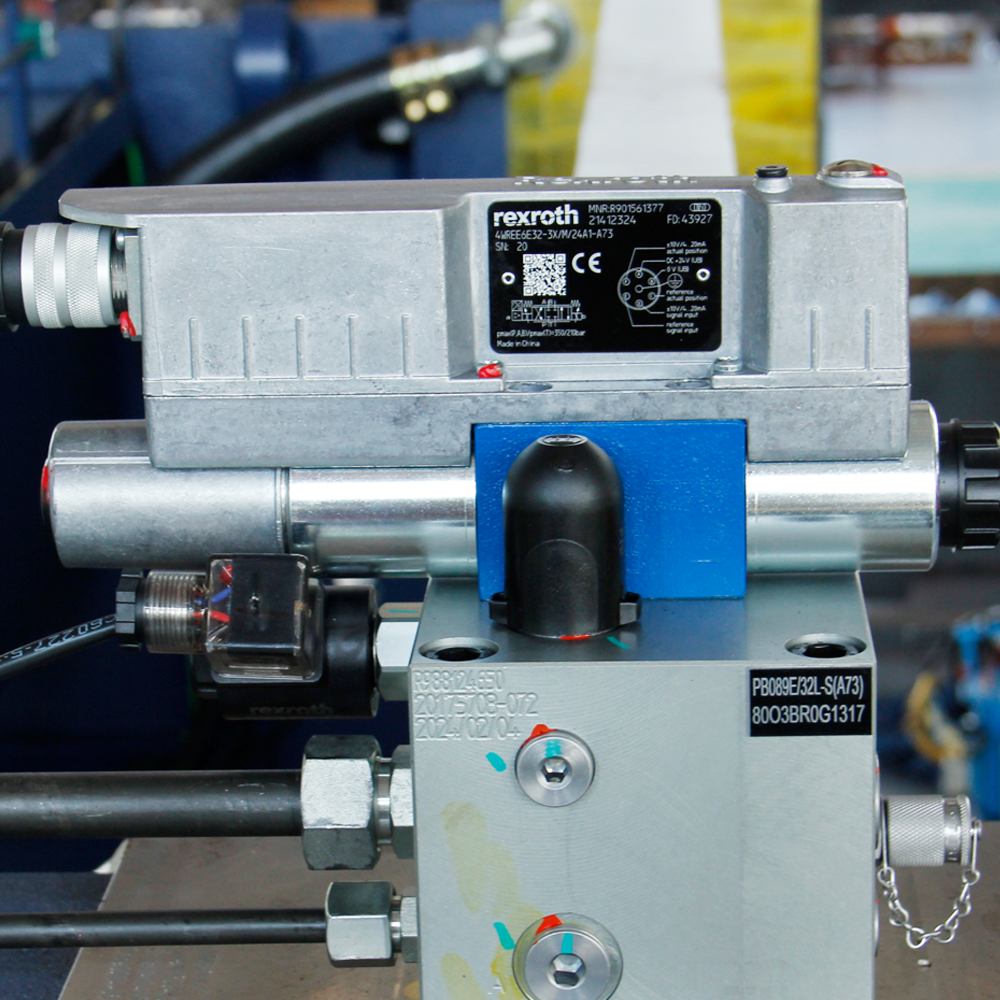

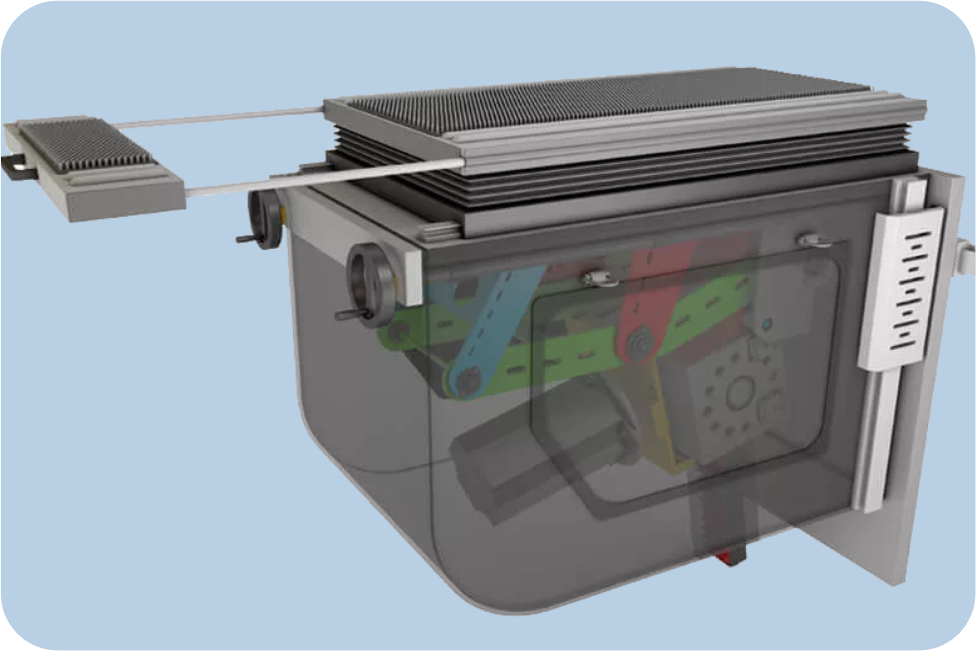

Hydraulic system (Standard)

Adoption of German Rexroth integrated hydraulic control system,Thanks to the high frequency response proportional valve, the synchronization precision of Y1 and Y2 axis in high speed operation is largely improved for higher bending efficiency

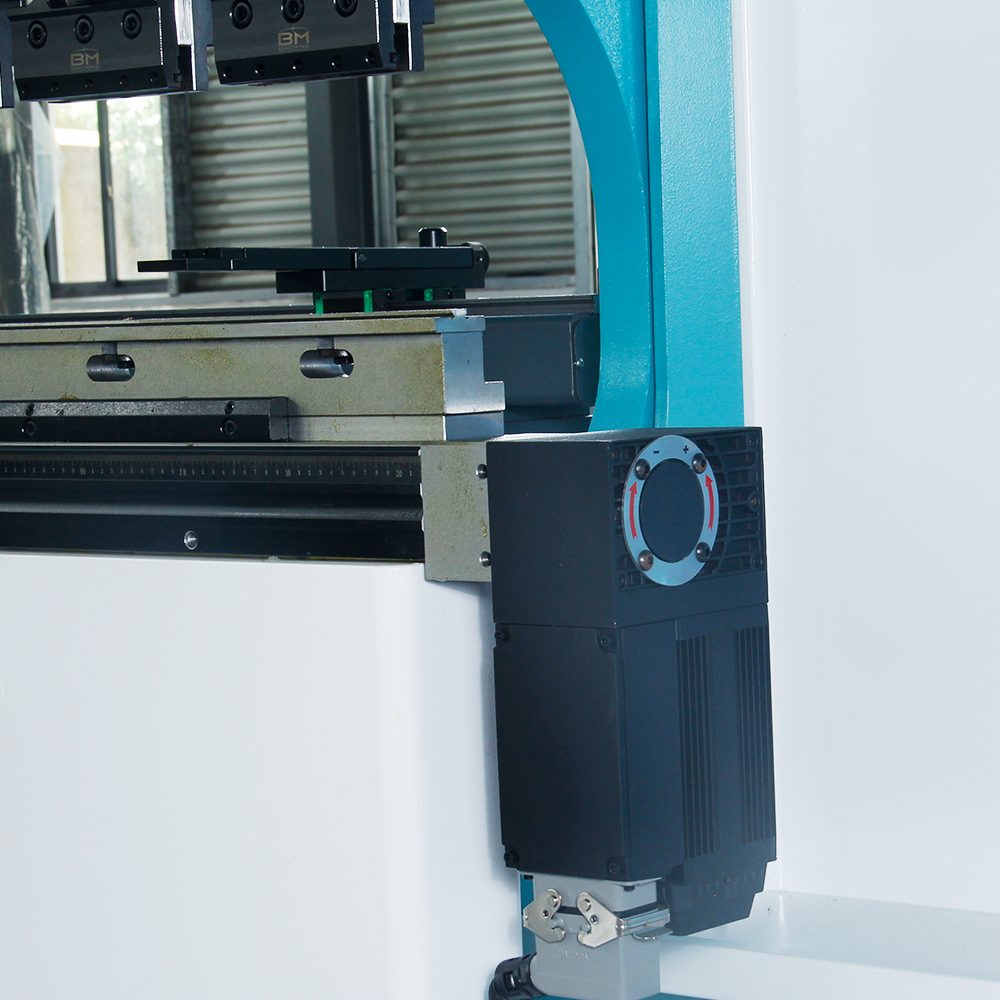

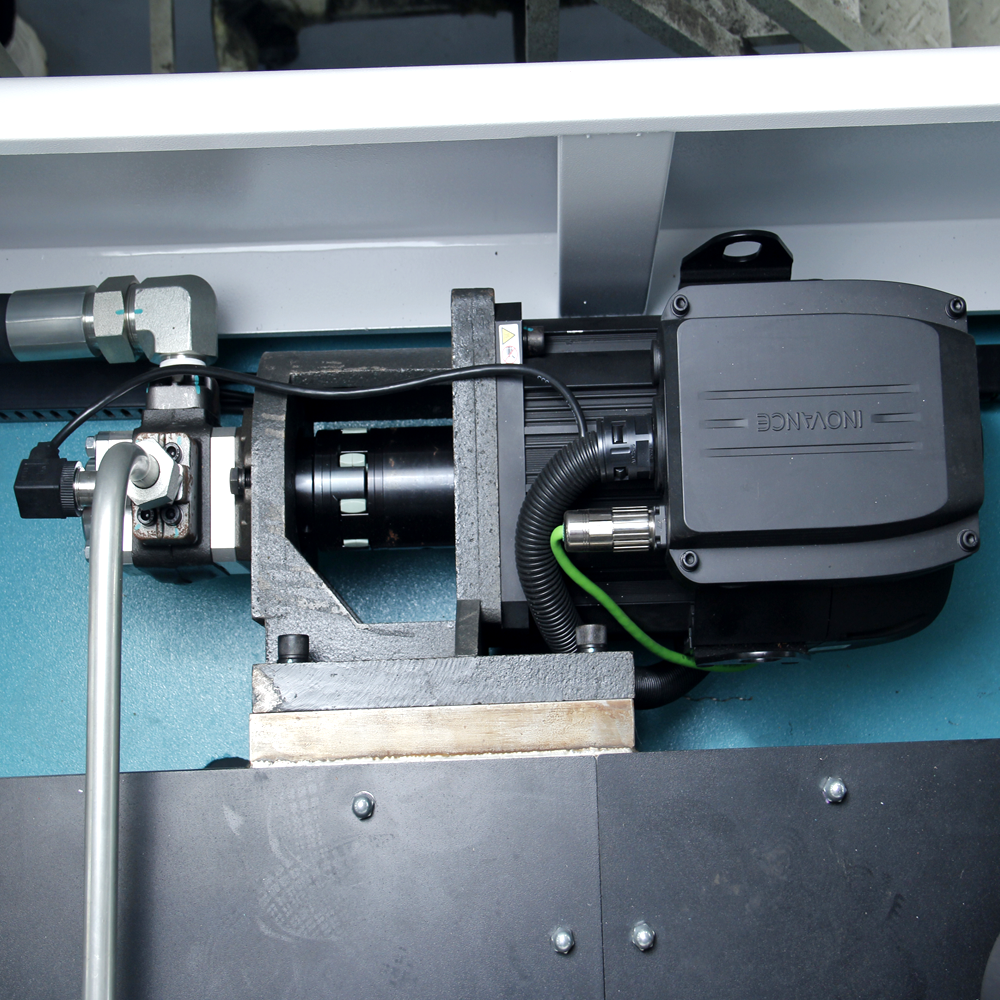

Inovance Servo Drives and Motors (Standard)

Inovance system is an innovative servo drive for press brakes,

1. Using servo motor as the main power source of hydraulic pump can save about 40% energy.

2. The overall efficiency of the slider increases by about 7-20%.

3. Oil temperature can be reduced by about 10-20℃.

Sample

Application Industry

Technical Parameter

|

Specifications |

Model |

||||||||

|

HD1103 |

HD1104 |

HD1703 |

HD1704 |

HD2204 |

HD4004 |

HD6320 |

HD8025 |

||

|

Bending force |

KN |

1100 |

1100 |

1700 |

1700 |

2200 |

4000 |

630 |

800 |

|

Table length |

MM |

3200 |

4100 |

3200 |

4100 |

4100 |

4100 |

2000 |

2500 |

|

Table height |

MM |

900 |

900 |

900 |

900 |

900 |

1070 |

900 |

900 |

|

Column spacing |

MM |

2500 |

3480 |

2500 |

3480 |

3480 |

3300 |

1600 |

2000 |

|

Throat depth |

MM |

400 |

400 |

400 |

400 |

400 |

430 |

400 |

400 |

|

Slider stroke |

MM |

200 |

200 |

200 |

200 |

250 |

250 |

160 |

160 |

|

Maximum opening height |

MM |

470 |

470 |

470 |

470 |

470 |

530 |

470 |

470 |

|

Rapid descent speed |

MM/S |

200 |

200 |

180 |

180 |

180 |

100 |

180 |

220 |

|

Return speed |

MM/S |

160 |

160 |

160 |

160 |

160 |

130 |

180 |

220 |

|

Working speed |

MM/S |

13 |

13 |

12 |

12 |

12 |

8 |

15 |

20 |

|

Working precision |

MM |

Straight line:±0.2mm/m, |

Straight line:±0.2mm/m, |

Straight line:±0.2mm/m, |

Straight line:±0.2mm/m, |

Straight line:±0.2mm/m, |

Straight line:±0.2mm/m, |

Straight line:±0.2mm/m, |

Straight line:±0.2mm/m, |

|

NC Number of Axes |

|

4+1AXIS |

4+1AXIS |

4+1AXIS |

4+1AXIS |

4+1AXIS |

4+1AXIS |

4+1AXIS |

4+1AXIS |

|

CNC Controls |

|

DA53T/CT12 |

DA53T/CT12 |

DA53T/CT12 |

DA53T/CT12 |

DA53T/CT12 |

DA53T/CT12 |

DA53T/CT12 |

DA53T/CT12 |

|

Main motor power |

KW |

5.5*2 |

5.5*2 |

7.5*2 |

7.5*2 |

9*2 |

11*2 |

5.5*2 |

5.5*2 |

|

Number of oil cylinders |

pc |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

|

capacity of oil tanks |

L |

60*2 |

60*2 |

60*2 |

60*2 |

80*2 |

120*2 |

60*2 |

60*2 |

|

Outline dimension |

MM |

4000*1750*2860 |

5100*1750*2860 |

4000*1750*2860 |

5100*1750*2860 |

5100*1850*2960 |

5100*1950*3500 |

2500*1600*2700 |

3200*1600*2700 |

|

Machine weight |

KG |

8300 |

10000 |

10500 |

12000 |

14000 |

24000 |

7000 |

7500 |

|

Oil pump displacement |

CC |

10*2 |

10*2 |

13*2 |

13*2 |

16*2 |

25*2 |

10*2 |

10*2 |

|

Rated pressure |

KG |

280 |

280 |

280 |

280 |

280 |

260 |

280 |

280 |

|

Maximum pressure |

KG |

290 |

290 |

290 |

290 |

290 |

280 |

290 |

290 |

Configuration Sheet

Have Questions? Talk to Our Experts!

Related Products