Laser Welding Machine

Product Video

Advantage

Portable

The whole weight is 45kg, small size, easy to transport by Car. Small size goes a long way. Portable and lightweight, creating more possibilities for welding.

Air Cooling

Featuring a highly purified air-cooling design, our system ensures reliable performance, perfectly suited for prolonged welding operations. By minimizing environmental impact and the need for frequent maintenance, it offers optimal efficiency.

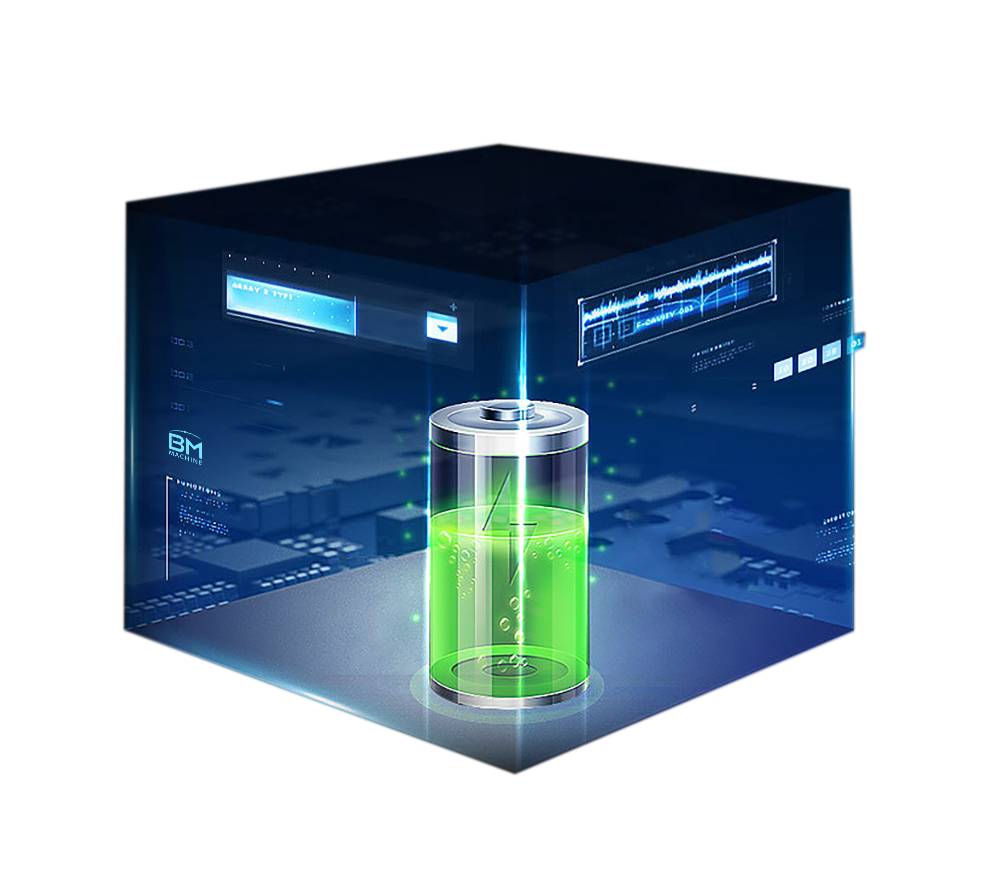

Energy Efficient

976nm pump technology, Electrical-optical conversion efficiency up to 42%.

Low e-cost, e-saving with 220VAC-16A.

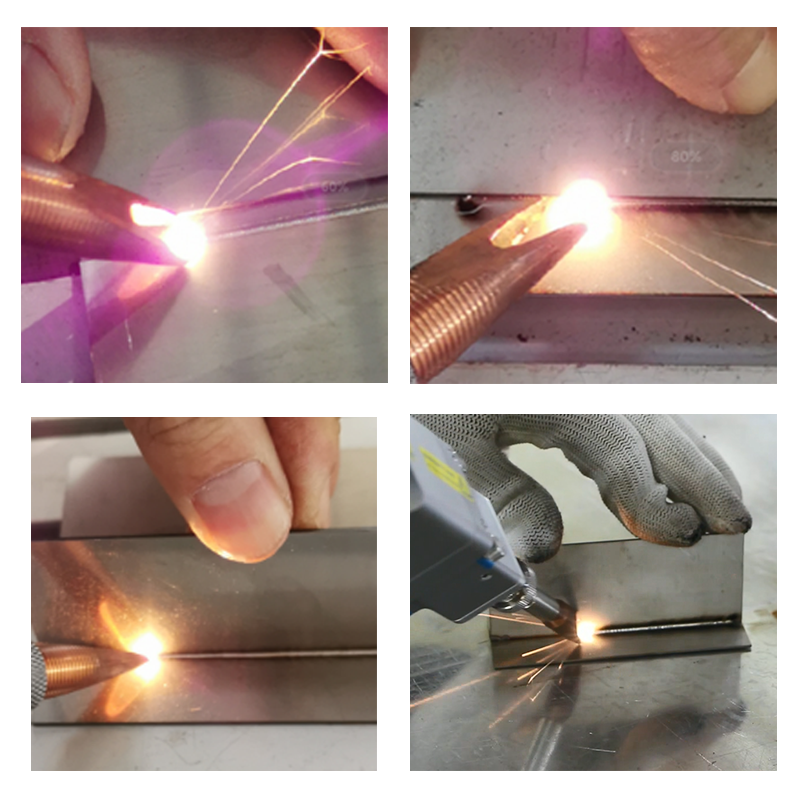

Better Welding Quality

The FMW-W fiber laser boasts exceptional stability in both laser power and beam profile, guaranteeing a consistently reliable process that yields high-quality welds with each operation. This non-contact method, devoid of any wearing surfaces, ensures that the final part produced matches the quality of the initial one, every time.

Better Welding Quality

The FMW-A fiber laser boasts exceptional stability in both laser power and beam profile, guaranteeing a consistently reliable process that yields high-quality welds with each operation.

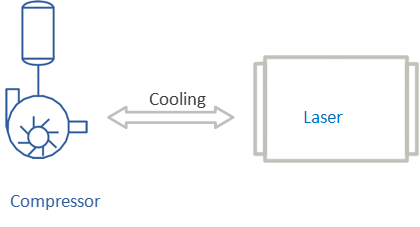

Air Cooling

• Combined compressor and Laser together.

• No water exist, reduce the cooling cycle.

• Highly integrated, smaller and lighter, higher refrigeration efficiency.

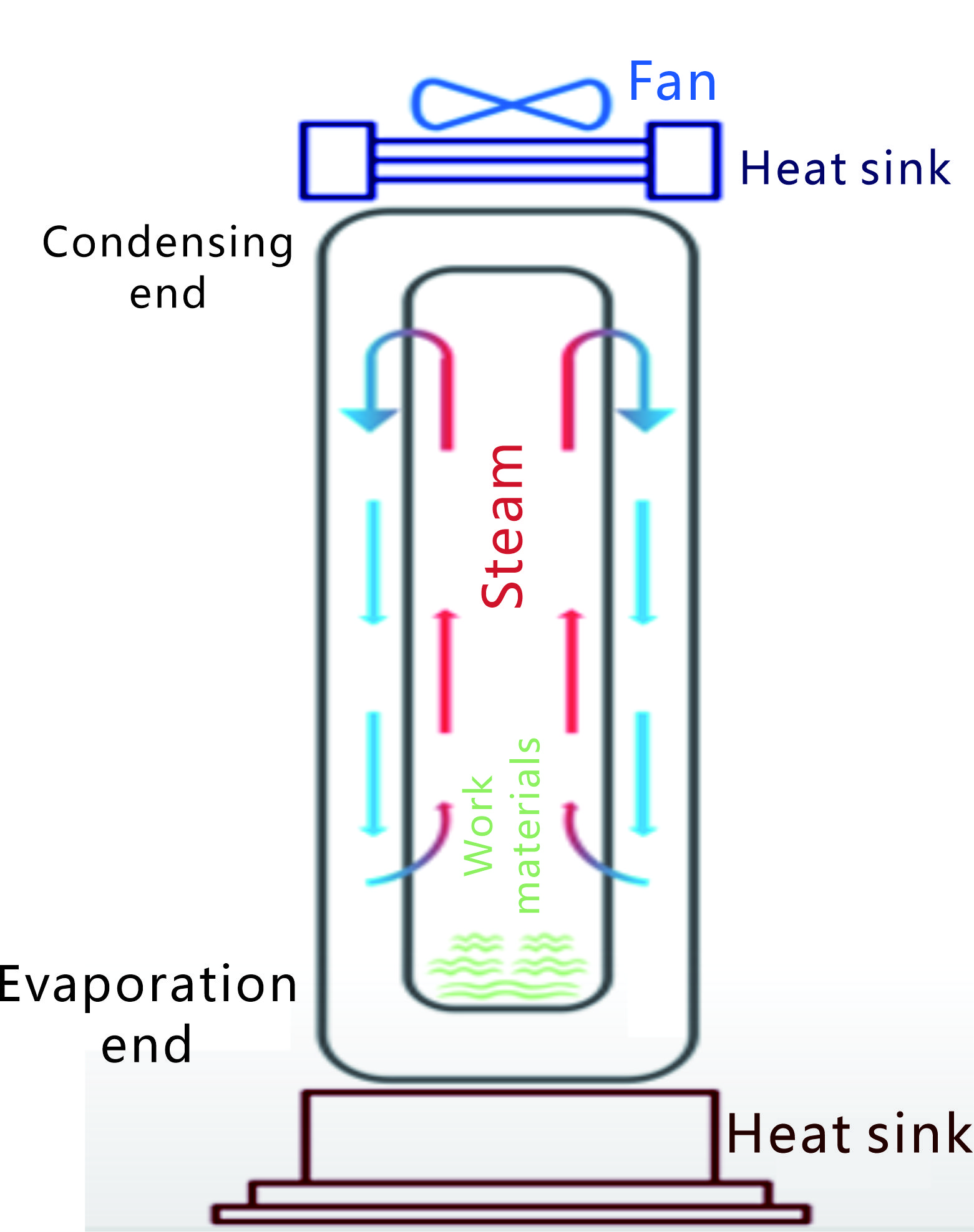

Air Cooling -- IPG

Thermal pipe cooling

Heat transfer is a physical process.

The working liquid at the evaporation end absorbs the heat inside the laser, and the liquid quickly evaporates into steam, flowing to the condensation end under pressure difference Steam transfers heat to the heat sink while condensing into a liquid The liquid flows back to the evaporation end by gravity, and the heat is discharged through the fan.

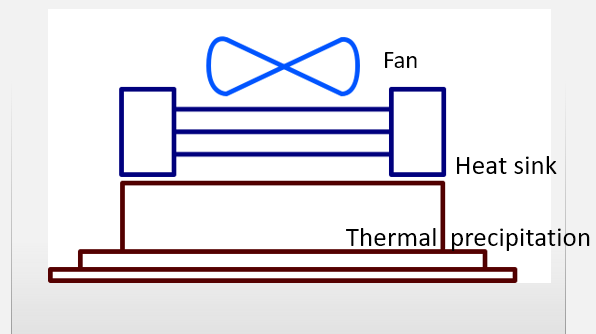

Air Cooling

✔ Sediments with good thermal conductivity (such as copper, aluminum nitride, etc.) are used to bring out the heat generated inside.

✔ Transfer heat from the hot sink to the heat sink (e.g. fins, fins, etc).

✔ Air convection is forced by a fan to dissipate the heat.

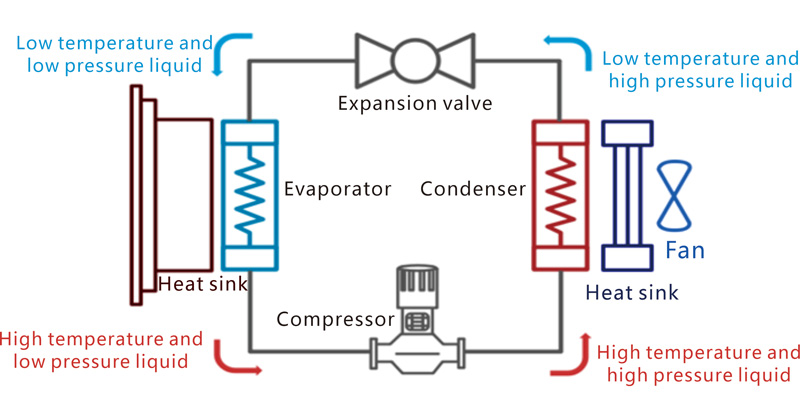

Air Cooling Solutions

✔ The compressor compresses the refrigerant into a high-temperature, high-pressure gas and flows to the condenser.

✔ The high-temperature gas condenses into a low-temperature liquid, and the heat generated by the liquefaction is discharged from the machine with the fan.

✔ The low temperature and high pressure liquid refrigerant becomes a low temperature and low pressure evaporation state after being reduced by the expansion valve, and flows to the evaporator.

✔ The cryogenic liquid refrigerant absorbs the surrounding heat and evaporates into a high-temperature gas, which reduces the internal temperature of the laser and achieves the effect of cooling.

✔ The evaporated gas refrigerant is again compressed by the compressor and cycled back and forth.

Sample

Application Industry

Technical Parameter

| Parameter | |

| Input working voltage /+/ - tolerance/Hz | AC220V (+/-15%) /50-60HZ |

| Chiller (water or air) | Cold coal refrigeration |

| Continuously load running (hour) | 24 Hours |

| Core diameter | 0.8/1.0/1.2/1.6 |

| Core diameter | 0.8/1.0/1.2/1.6 |

| Display control | LCD touch screen |

| Feeder dimension | 560*210*420mm |

| Laser gun weight | eight hundred can |

| Laser gun weight | eight hundred can |

| Laser Power (w) | 1500W |

| Laser power brand name/original | GW |

| Laser power brand name/original manufacturer | Kipling |

| Laser wavelength | 1070±10nm |

| Laser welding gun (type) | SUP205 |

| Laser welding gun (type) | ukT2 |

| Laser welding gun (type) | ukT2 |

| Laser welding gun in detail features / functions / modes | Adjustable screen display |

| Laser welding gun in detail features/functions/modes | Adjustable screen display |

| Power | 1500W-2000W |

| Welder speed range | 40-60cm/min |

| Welding source (machine) Dimension | 540*540*290mm |

| Welding source (machine) weight | 38Kg |

| Welding spot mode | simple pendulum |

| Welding spot size | 0-5mm |

| Welding thickness | 0.5-5mm |

| Working temperature | -10 ~ 60 degree |

Configuration Sheet

Have Questions? Talk to Our Experts!

Related Products