Water Cooling Welding Machine

Product Video

Advantage

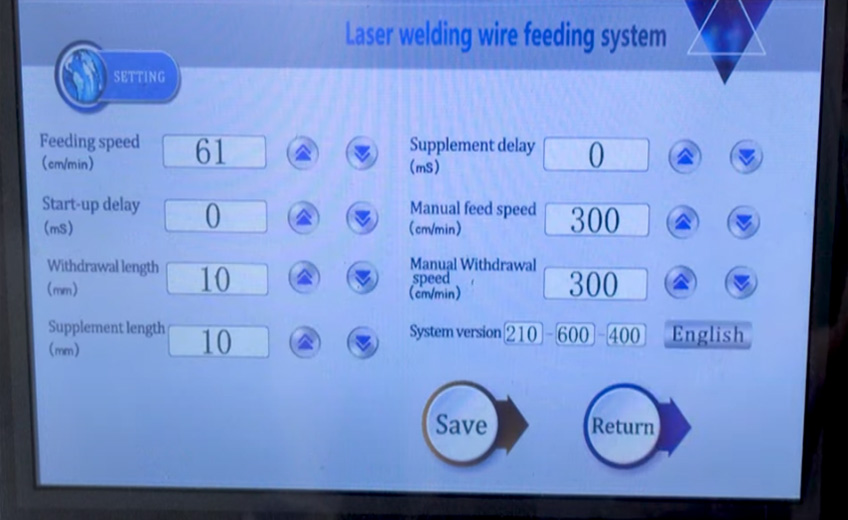

BMMachine Welding Control System

✔ Easy to use, all parameters can be quickly adjusted.

✔ Quickly adjust the laser position without worrying about laser deviation

✔ More safety settings for better protection of users and observers

✔ Accurate preset parameters that can be selected with a simple click to start welding.

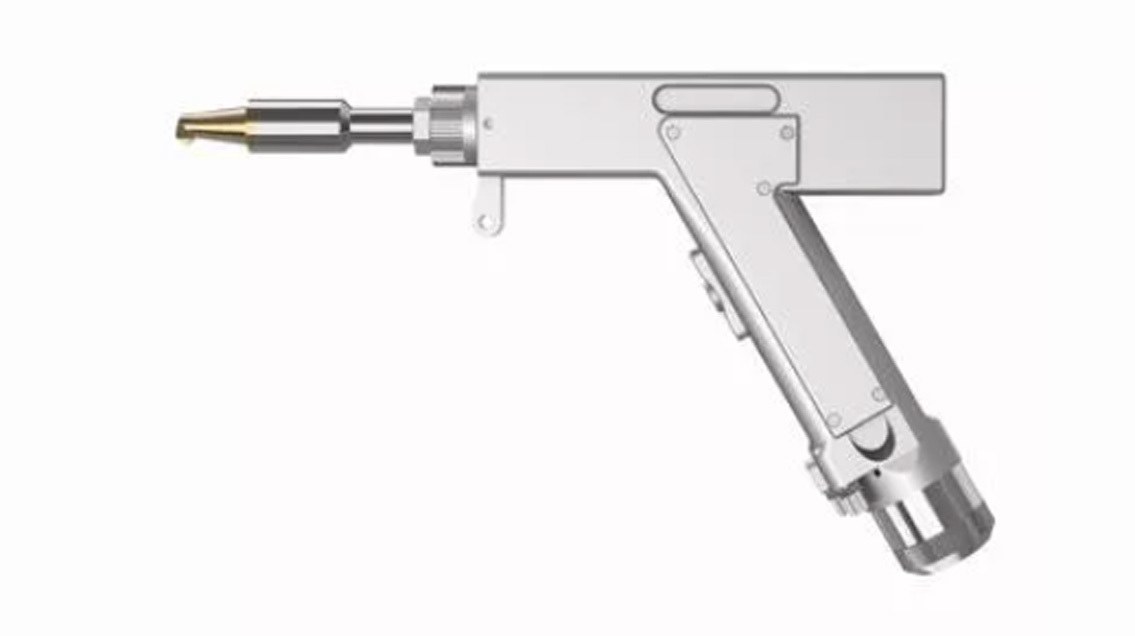

Laser Welding Head

✔ 3-in-1 multifunctional laser head with welding, remote cleaning and seam cleaning functions

✔ Individual air-cooled design channel, four hours (with test records) of stable operation without overheating

✔ Ergonomically designed welding machine with a physical safety off button for easy stop / start even with welding gloves on

Automatic Wire Feeder

✔ All newly designed automatic wire feeders could feed up to 2mm of wire.

✔ Double Wire feeding available

✔ Wire feeder is designed to complement the welding machine

✔ Physical button, easy to operate even with welding gloves on

Water Chiller

✔ Designed with independent modules for easy maintenance and replacement

✔ Accurate calculation and design of cooling capacity, providing maximum cooling effect with minimal power consumption, can meet the needs of long-term continuous operation

✔ All use R410a refrigerant that meets environmental requirements

Sample

Application Industry

Technical Parameter

| Prameter | |

| Power Out (w) | 1500W |

| Working type | CW/Modulation/Pulse/Linear/Timing |

| Output power adjustment range(%) | 1-100% |

| Output laser wavelength (nm) | 1075 +/ 10 nm |

| Power stability | <2% (temperature 25 +/- 1°) |

| Maximum modulation frequency | 50kHz |

| Laser response time | <10us |

| Indicating laser wavelength (nm) | 650nm |

| Adjustable range of Indicator light power (milliwatts) | <1mW |

| Input voltage | 220VAC/50Hz/60Hz |

| Power consumption | <= 4.8 kW |

| Working environment temperature range | 10 - 45°C |

| Working environment humidity range | <=85 degree |

| Control port | CON10 |

| HMI | 7 inch |

| Interface Type | Handheld Welding Head |

| Collimation focal length | 50mm |

| Focus focal length | 150mm |

| Transmission length | Standard length 5 +/- 0.5m (others can be customized) |

| Minimum cooling capacity | 2.25KW |

| Minimum flow requirement | 15L/min |

| Coolant temperature range | 25 +/- 1°C |

| Coolant Hydraulic Requirements | 5~6 bar |

| Torch tip cooling and shielding gas | inert gas |

| Handheld Welding Head Dimensions | 296*39*147 [ mm] (L x W x H) |

| Handheld Welding Head Weight | 680g |

| Maximum Wire Feed Spool Size | 300*100 |

| Wire feeding weight | <7Kg |

| Overall size | 950*440*780 [ mm] (L x W x H) |

| Weight (total) | <85[ kg] |

Configuration Sheet

|

Model |

HW-3000 |

|

|

Maximum Laser Power |

|

3000 |

|

Laser Frequency |

HZ |

50-5000HZ |

|

Power Adjustment Range |

% |

10-100 |

|

Power Instability |

% |

<3 |

|

Welding Penetration(stainless steel) |

mm |

5.0 |

|

Welding Penetration(carbon steel) |

mm |

5.0 |

|

Welding Penetration(aluminum steel) |

mm |

6 |

|

Swing Welding Spot |

mm |

Solder Spot 2-4 |

|

Input Voltage |

|

380V/50HZ |

|

Total Power |

KW |

≤3 |

|

Automatic Wire Feeding |

|

Optional |

Have Questions? Talk to Our Experts!

Related Products