Pure Electric servo CNC bending machine

Product Video

Electric drive, does not require hydraulic oil

Save about 70% energy compared to traditional machines

No vibration during operation, noise and sound pressure ≤ 40dB

Reduce accuracy interference points by approximately 60%

Direct drive servo motor with high response speed

Zero fault, long service life

Advantage

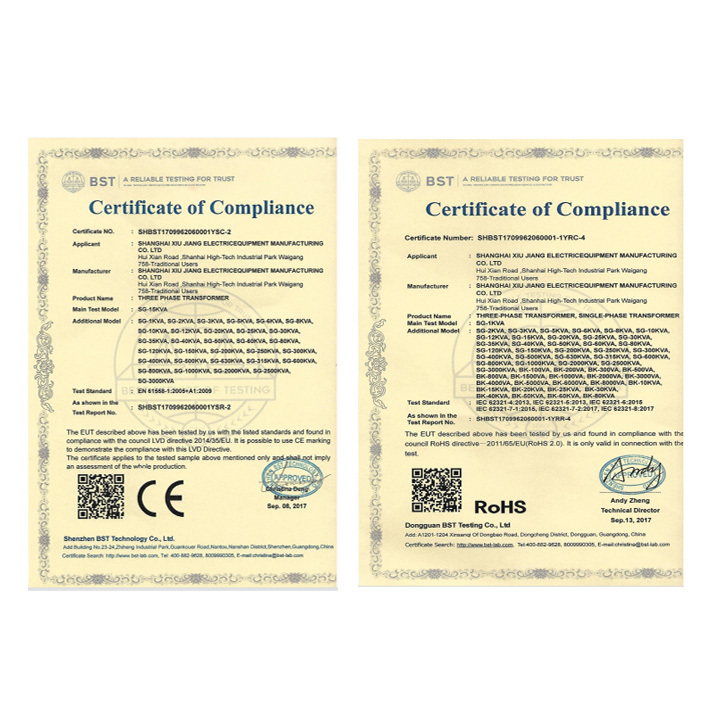

Transformer : SG-15Kw

Transformer is a kind of static electrical equipment that transform voltage current between two or among more winding depending on electromagnetic induction with same frequency. SG and SBK type three-phase dry type transformers whose body that is composed of iron core, winding and so on will not be immersed in insulating liquid medium (transformer oil), but will be exposed in air directly, and carryout heat dispersion by making use of air convection.

DSP LASER - laser safety devices

The safety device DSP LASER is a visible laser emission guard which, inserted in a more general control system, contributes to protect the operator in the use of press brakes for the cold working of the metals and is constituted by:

✔ one transmitter DSP LASER TX powered at 24Vac or 24Vdc,

✔ one receiver DSP LASER RX powered at 24Vac or 24Vdc which moreover includes:

the logic for the control of the operation modes, the function of automatic monitoring of the overtravel and the two solid-state outputs OSSD,

✔ one DSP LASER AL module (optional) with a series of variations.

WILA - Holland WILA hydraulic clamping systems

WILA's clamping system makes it possible to quickly replace molds.

The clamping and loosening action is automatically controlled by the electrical system, with a strong and reliable clamping force, providing maximum accuracy, flexibility, durability, and safety for quick mold re-placement.

Sample

Servo motor drive

Double sided quick clip

4-axis rear shift material

The SANYO DENKI CNC system

Double V same core CNC mold

The electronic control system

Application Industry

Technical Parameter

| Specifications | Model | ||

| PS4013 | PS6020 | ||

|

Bending force |

KN | 400 | 600 |

|

Table length |

MM | 1390 | 2150 |

|

Table height |

MM | 60 | 60 |

|

Column spacing |

MM | 1300 | 2000 |

|

Throat depth |

MM | 350 | 350 |

|

Slider stroke |

MM | 120 | 120 |

|

Maximum opening height |

MM | 430 | 430 |

|

Approach speed |

MM/S | 120 | 120 |

|

Return speed |

MM/S | 120 | 120 |

|

Working speed |

MM/S | 30 | 30 |

|

X-axis stroke |

MM | 450 | 450 |

|

X-axis maximum operating speed |

MM/S | 300 | 300 |

|

X-axis positioning accuracy |

MM | 0.005 | 0.005 |

|

X-axis repeat positioning accuracy |

MM | 0.01 | 0.01 |

|

Y-axis positioning accuracy |

MM | 0.01 | 0.01 |

|

Y-axis repeat positioning accuracy |

MM | 0.01 | 0.01 |

|

R-axis stroke |

MM | 100 | 100 |

|

R-Axis Maximum Operating Speed |

MM/S | 50 | 50 |

|

Working precision |

MM | 0.2 | 0.2 |

|

NC Number of Axes |

6 | 6 | |

|

Main motor power |

KW | 6.5*2 | 15*2 |

|

Outline dimension |

2000*1500*2550 | 2550*1500*2600 | |

|

Machine weight |

KG | 3500 | 5500 |

|

Rated pressure |

KG | 280 | 280 |

|

Maximum pressure |

KG | 290 | 290 |

Configuration Sheet

Have Questions? Talk to Our Experts!

Related Products