Detailed explanation and latest progress of laser surface nanomaterialization technology

Release Time:

Jan 10,2022

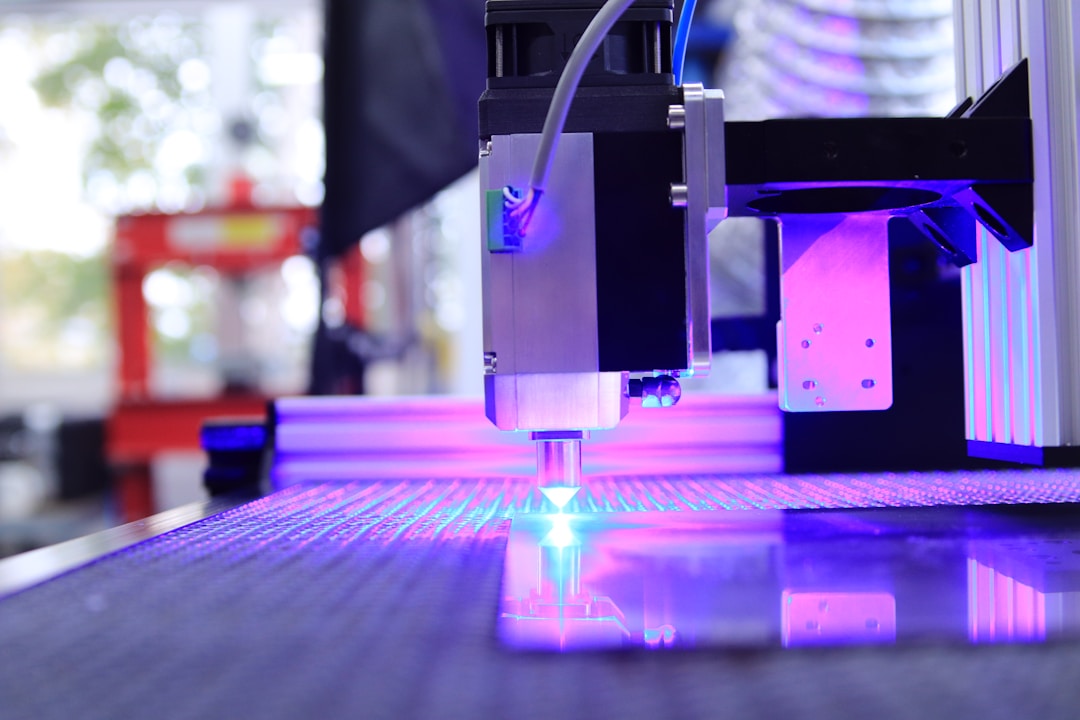

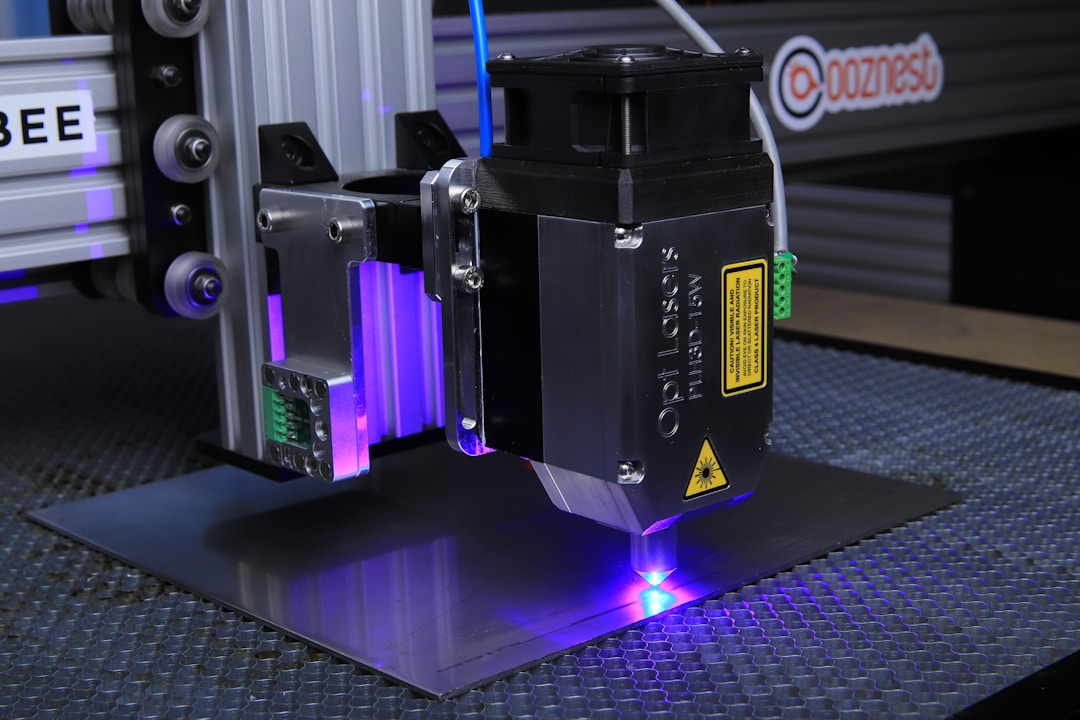

After the successful development of high-power lasers in the 1970s, laser surface treatment technology entered practical applications and rapidly developed, including laser quenching (laser phase change hardening surface modification technology), laser remelting, and laser surface alloying

After the successful development of high-power lasers in the 1970s, laser surface treatment technology entered practical applications and rapidly developed, including laser quenching (laser phase change hardening surface modification technology), laser remelting, and laser surface alloying

Laser surface nanomaterialization technology includes surface material grain nanomaterialization and the realization of surface nanostructures.

The various excellent properties of nanomaterials and nanostructures have gradually been recognized. For metal materials, if the grain size is refined to the nanometer level, their comprehensive performance will be greatly improved. At the same time, the nano patterned structure on the surface of metal materials can greatly improve the surface performance of materials, making them have a series of excellent properties such as oxidation resistance, wear resistance, corrosion resistance, superhydrophobicity, etc.

There are various methods for surface nanomaterialization of materials, and there is a major category among various surface nanomaterialization technologies, which combines laser surface treatment technology and nanotechnology to achieve surface layers with nano characteristics. They can be collectively referred to as laser surface nanomaterialization technology;

Or more broadly, it is called laser nanosurface engineering technology, which directly or mainly uses laser as a specific technical means to directly change or add materials to change the morphology, composition, or structure of the surface of the processed solid material, forming a surface layer containing nano grains or certain nano particle components.

Alternatively, methods such as laser etching, laser imprinting, laser texturing, and laser micro/nano shaping can be used to achieve nanostructures on the material surface.

Introduction: After the successful development of high-power lasers in the 1970s, laser surface treatment technology entered practical applications and rapidly developed, including laser quenching (laser phase change hardening surface modification technology), laser remelting, and laser surface alloying

Laser surface nanomaterialization technology includes surface material grain nanomaterialization and the realization of surface nanostructures.

The various excellent properties of nanomaterials and nanostructures have gradually been recognized. For metal materials, if the grain size is refined to the nanometer level, their comprehensive performance will be greatly improved. At the same time, the nano patterned structure on the surface of metal materials can greatly improve the surface performance of materials, making them have a series of excellent properties such as oxidation resistance, wear resistance, corrosion resistance, superhydrophobicity, etc.

There are various methods for surface nanomaterialization of materials, and there is a major category among various surface nanomaterialization technologies, which combines laser surface treatment technology and nanotechnology to achieve surface layers with nano characteristics. They can be collectively referred to as laser surface nanomaterialization technology;

Or more broadly, it is called laser nanosurface engineering technology, which directly or mainly uses laser as a specific technical means to directly change or add materials to change the morphology, composition, or structure of the surface of the processed solid material, forming a surface layer containing nano grains or certain nano particle components.

Alternatively, methods such as laser etching, laser imprinting, laser texturing, and laser micro/nano shaping can be used to achieve nanostructures on the material surface.

Language

Language