Laser treatment reduces adhesion: superhydrophobicity, superoleophobicity, and superoleophobicity

Release Time:

Nov 09,2021

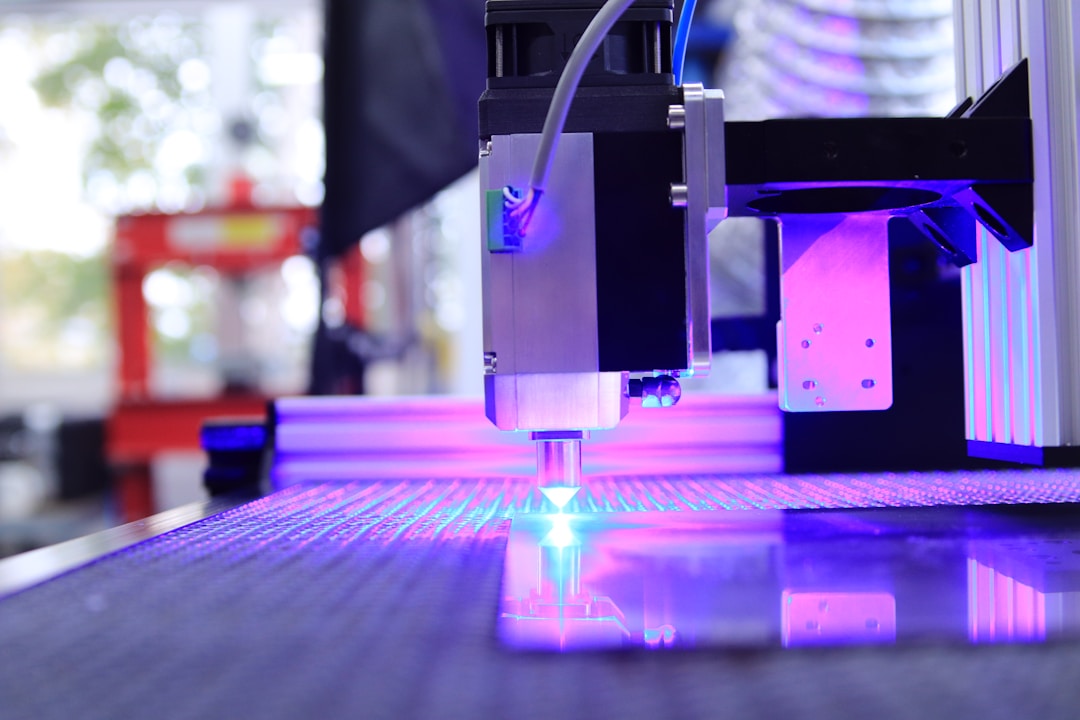

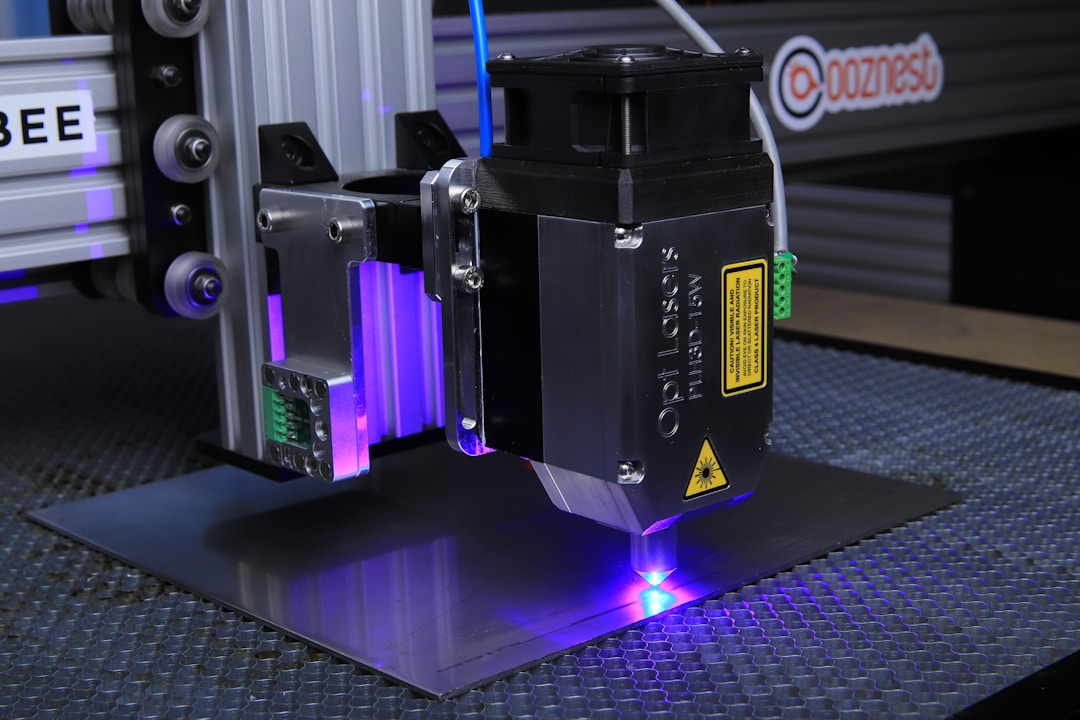

A three-layer microstructure was formed on the surface of stainless steel through simple femtosecond laser ablation. The structural surface exhibits superhydrophilicity in air and superhydrophobicity/superhydrophobicity in water. After further modification with stearic acid, the surface becomes superhydrophobic and underwater superoleophilic/superoleophilic. Through this technology, the nozzle of the needle is modified to have super wettability. When the nozzle is used to release liquids and gases, the size of the distributed water, oil droplets, and bubbles is significantly reduced. We have demonstrated that underwater superhydrophobic nozzles can distribute nanoliter volume of bubbles without reducing the nozzle diameter. It also effectively prevents liquid retention at the opening of the needle. Therefore, the reduction in droplet/bubble size and retention rate enables us to significantly improve volume accuracy and resolution during the operation and transportation of aqueous solutions and gases. Femtosecond laser induced ultra humid nozzles can be used for high-resolution liquid transfer, inkjet printing, 3D printing, pipettes, medical equipment, cell engineering, biological detection, microchemical reactors, and reducing industrial gas emissions.

A three-layer microstructure was formed on the surface of stainless steel through simple femtosecond laser ablation. The structural surface exhibits superhydrophilicity in air and superhydrophobicity/superhydrophobicity in water. After further modification with stearic acid, the surface becomes superhydrophobic and underwater superoleophilic/superoleophilic. Through this technology, the nozzle of the needle is modified to have super wettability. When the nozzle is used to release liquids and gases, the size of the distributed water, oil droplets, and bubbles is significantly reduced. We have demonstrated that underwater superhydrophobic nozzles can distribute nanoliter volume of bubbles without reducing the nozzle diameter. It also effectively prevents liquid retention at the opening of the needle. Therefore, the reduction in droplet/bubble size and retention rate enables us to significantly improve volume accuracy and resolution during the operation and transportation of aqueous solutions and gases. Femtosecond laser induced ultra humid nozzles can be used for high-resolution liquid transfer, inkjet printing, 3D printing, pipettes, medical equipment, cell engineering, biological detection, microchemical reactors, and reducing industrial gas emissions.

Due to its wide range of applications, such as liquid transportation, inkjet printing, high-resolution 3D printing, cell engineering, microreactors, biological analysis, biosensing, energy production, chemical engineering, and environmental remediation, the generation and manipulation of small droplets (up to micro or nano scale) and fine bubbles are receiving increasing attention. The scientific and industrial communities have made significant efforts to generate smaller droplets by reducing nozzle size or utilizing special driving mechanisms such as droplets. However, traditional nozzles and dispensing methods still face many limitations. In addition, if the nozzle size of the needle is reduced to the limit specified by existing manufacturing technology, it will be difficult to further reduce the volume of the dispensed droplets. In fact, the adhesion and retention of liquids on ordinary nozzles are the most serious problems in many biomedical and chemical applications, as they reduce volume accuracy and increase the risk of cross contamination. In order to overcome the above problems, a superhydrophobic microstructure has recently been coated on the surface of commercial syringe needles, which can greatly improve the ability of the nozzle to spray small water droplets.

In nature, the surfaces of many animals and plants exhibit various special wettability. Natural phenomena inspire us to design special wetting properties on solid substrates by combining chemical composition and layered surface micro/nanostructures, while reducing adhesion between needle shaped nozzles and water droplets/oil droplets/bubbles.

Here, we have developed a simple method to achieve different superhydrophobicity on stainless steel surfaces through femtosecond laser treatment, including superhydrophobicity and superhydrophilicity in air, superhydrophobicity, superhydrophobicity, superhydrophobicity, and superhydrophilicity in water. The influence of surface superhumidity of stainless steel nozzles on the volume of water droplets, underwater oil droplets, and underwater bubbles in the nozzle was systematically studied. We found that laser-induced superhydrophobicity, underwater superoleophobicity, and underwater superoleophobicity can significantly reduce the size of water droplets, oil droplets, and bubbles separated from the structural nozzle, avoiding liquid retention at the needle mouth.

Language

Language