Laser nanomanufacturing technology

Release Time:

Apr 02,2024

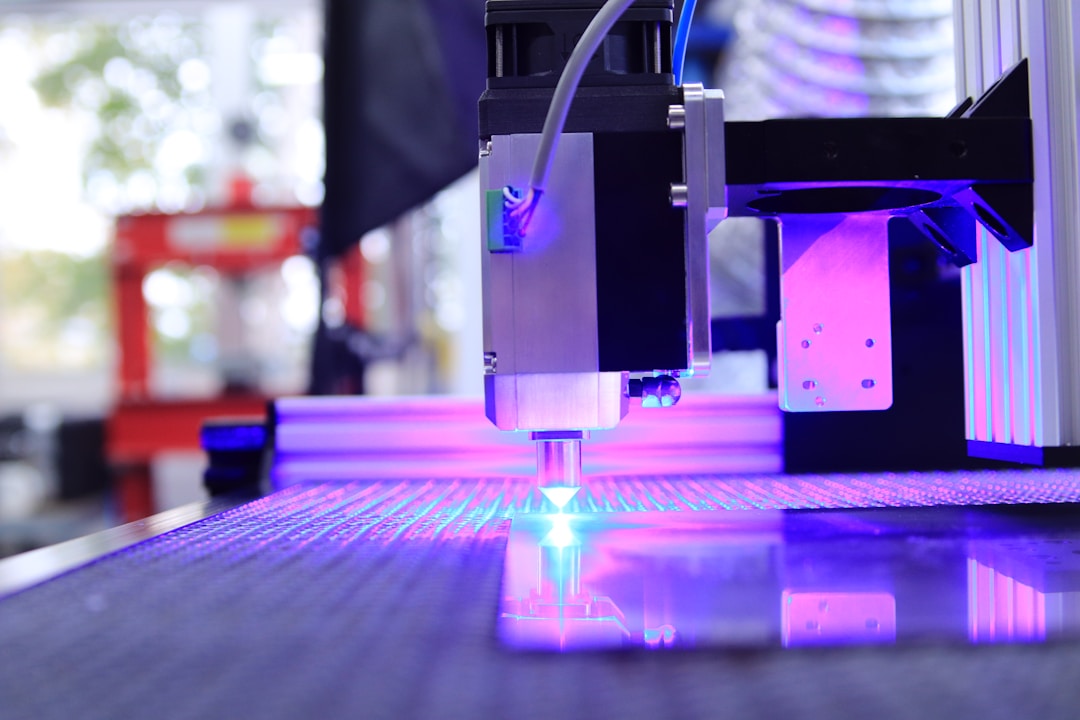

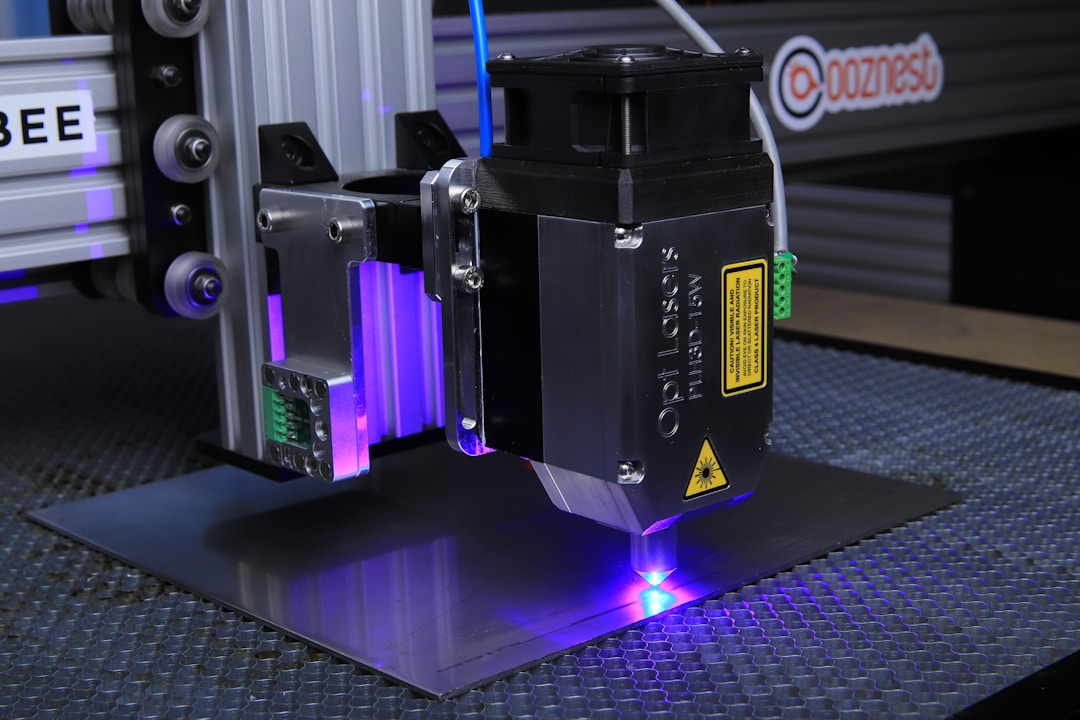

Micro manufacturing technology is a cutting-edge and interdisciplinary field that gradually developed in the late 1980s and early 1990s. Its rapid development will bring about a revolutionary change in almost all industrial sectors in the 21st century. The widespread application of micro manufactured products will trigger a new technological revolution, just like the impact of microelectronics technology on the world. This is a high-tech challenge and opportunity, which may become a breakthrough for China to catch up with the world's advanced level and leap towards high-tech. Nanotechnology and laser processing technology are the core of micro manufacturing technology.

Micro manufacturing technology is a cutting-edge and interdisciplinary field that gradually developed in the late 1980s and early 1990s. Its rapid development will bring about a revolutionary change in almost all industrial sectors in the 21st century. The widespread application of micro manufactured products will trigger a new technological revolution, just like the impact of microelectronics technology on the world. This is a high-tech challenge and opportunity, which may become a breakthrough for China to catch up with the world's advanced level and leap towards high-tech. Nanotechnology and laser processing technology are the core of micro manufacturing technology.

Nanotechnology

Nanotechnology typically refers to materials, design, manufacturing, measurement, and control technologies at the nanoscale. Nanotechnology involves multiple fields such as mechanics, electronics, materials, physics, chemistry, biology, and medicine. Nanotechnology and nanomanufacturing technology are important cutting-edge fields in the 21st century, which will bring about greater changes in people's production and lifestyle.

Nanofabrication

Nanomanufacturing refers to the production of nanomaterials such as nanoparticles, nanowires, nanotubes, surface nanostructures, and the manufacturing of three-dimensional nanostructures/devices, with at least one dimension of the characteristic size of the manufactured object between 1 and 100 nm. Devices and products with smaller size, stronger functionality, higher efficiency, fewer consumables, and lower energy consumption are constantly being pursued by the industry. Especially with the development of manufacturing technology from the micrometer scale to the nanometer scale, higher requirements have been put forward for the processing ability of feature sizes below 100 nm.

Nanomanufacturing technology involves ultra precision machining technology, precision measurement, sensing and control technology, among which nanoscale machining technology is its core, which can be divided into two aspects: machining accuracy and machining scale. The machining accuracy has evolved from the highest accuracy of 10Lm at the beginning of this century to 20nm with a surface roughness of 2-5nm. The precision of ultra precision diffraction gratings processed with diamond lathes has reached 1nm. At present, the positioning accuracy of the machining center is about 2 μ m. The positioning accuracy of the coordinate grinder is about 1 μ M; For IC graphics production equipment, its calibration and exposure machine positioning accuracy is about 50nm. The laboratory can produce lines, columns, and grooves below 10nm. The precision or scale of nanomachining is on the order of atomic size, and its processing techniques include ultra precision machining, lithography, energy beam machining, and scanning probe microscopy machining.

Language

Language