Direct femtosecond laser surface nanostructures/microstructures and their applications

Release Time:

Nov 12,2021

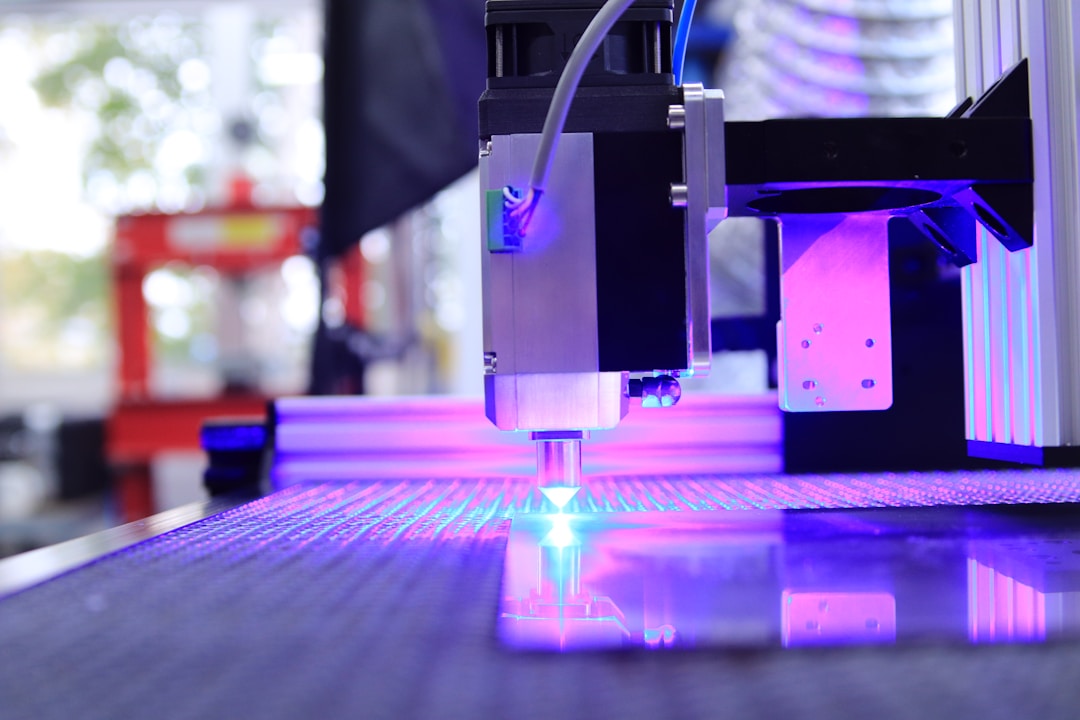

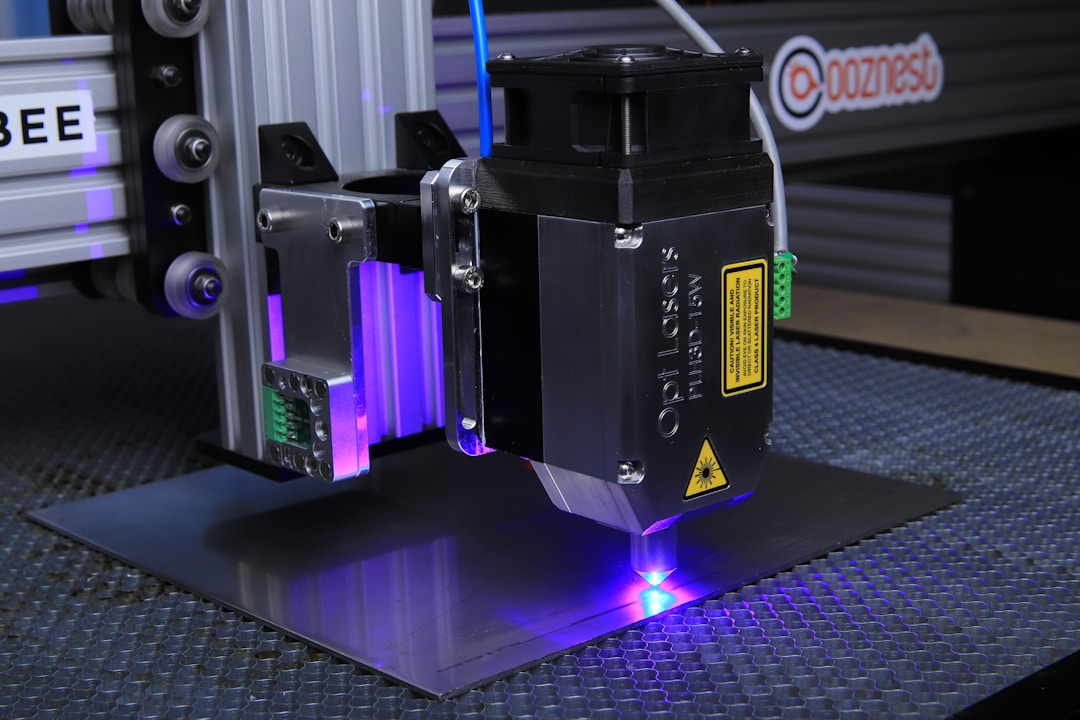

Surface morphology is a key factor in controlling the optical, mechanical, wetting, chemical, biological, and other properties of solid surfaces. In recent years, femtosecond laser surface nanostructures have become a new and multifunctional technology used to produce various nanostructured materials, suitable for wide applications in photonics, plasma electronics, optoelectronics, biochemical sensing, micro/nanofluidics, optofluidics, biomedical and other fields. In the past decade, this technology has received a lot of research attention due to the following advantages: (1) it can process almost all types of materials, including metals, semiconductors, glass, and polymers; (2) Non planar machining capability; (3) Capable of generating nanostructures in the surface region from microscale to macroscopic scale; (4) Under normal environmental conditions, maskless single-step high-speed processing is required without the need for a clean room environment.

In the past few years, direct femtosecond laser surface treatment has distinguished itself from other traditional laser ablation methods and has become one of the best methods for creating nanoscale and microscale surface structures on metals and semiconductors due to its flexibility, simplicity, and scalability, as well as the controllability to create various types of nanoscale/microstructures suitable for wide applications. Recently, significant progress has been made in applying this technology to alter the optical properties of metals and semiconductors. Therefore, high absorption metals and semiconductors are produced, known as "black metals" and "black silicon". In addition, by coloring the metal structure, various colors other than black have been created. Direct femtosecond laser processing can also produce new materials with wetting properties ranging from superhydrophilicity to superhydrophobicity. In extreme cases, supercore absorbing materials are produced, which can allow liquids to flow vertically upwards against gravity on an extended surface area. Despite impressive scientific achievements so far, femtosecond laser direct processing remains a young research field, and many exciting discoveries are expected to emerge.

1. Introduction

Surface morphology is a key factor in controlling the optical, mechanical, wetting, chemical, biological, and other properties of solid surfaces. In recent years, femtosecond laser surface nanostructures have become a new and multifunctional technology used to produce various nanostructured materials, suitable for wide applications in photonics, plasma electronics, optoelectronics, biochemical sensing, micro/nanofluidics, optofluidics, biomedical and other fields. In the past decade, this technology has received a lot of research attention due to the following advantages: (1) it can process almost all types of materials, including metals, semiconductors, glass, and polymers; (2) Non planar machining capability; (3) Capable of generating nanostructures in the surface region from microscale to macroscopic scale; (4) Under normal environmental conditions, maskless single-step high-speed processing is required without the need for a clean room environment.

Language

Language