Fabric Laser Cutting Machine

Product Video

Advantage

(1)Limitless Patterns

- Lasers are able to cut the most detailed patterns that you can imagine.

(2)No fraying of fabric

- Some fabrics will fray easily when cut with shears or blades.

- BM fabric laser cutting machine can seal the edges of most textiles, virtually eliminating the problem of fraying.

(3)Higher efficiency operations, less material wastage, and other cost saving benefits

- Cutting precisely with scissors or blades can be very challenging, especially if high volumes are needed.

- With laser cutting (even on leather), you can have repeatable clean cuts with a precision unachievable with shears or blades.

(4)No limit for textile length

- Laser Cutting Shapes can cut endless lengths limited only by the length of your roll of fabric.

- There is textile roller mounted on laser machine, which could hold textile and feed textile.

(5)Suitable for Mass Production

- Featuring high-speed cutting, precise consistency, automated operation, and robust durability, making it ideal for mass production.

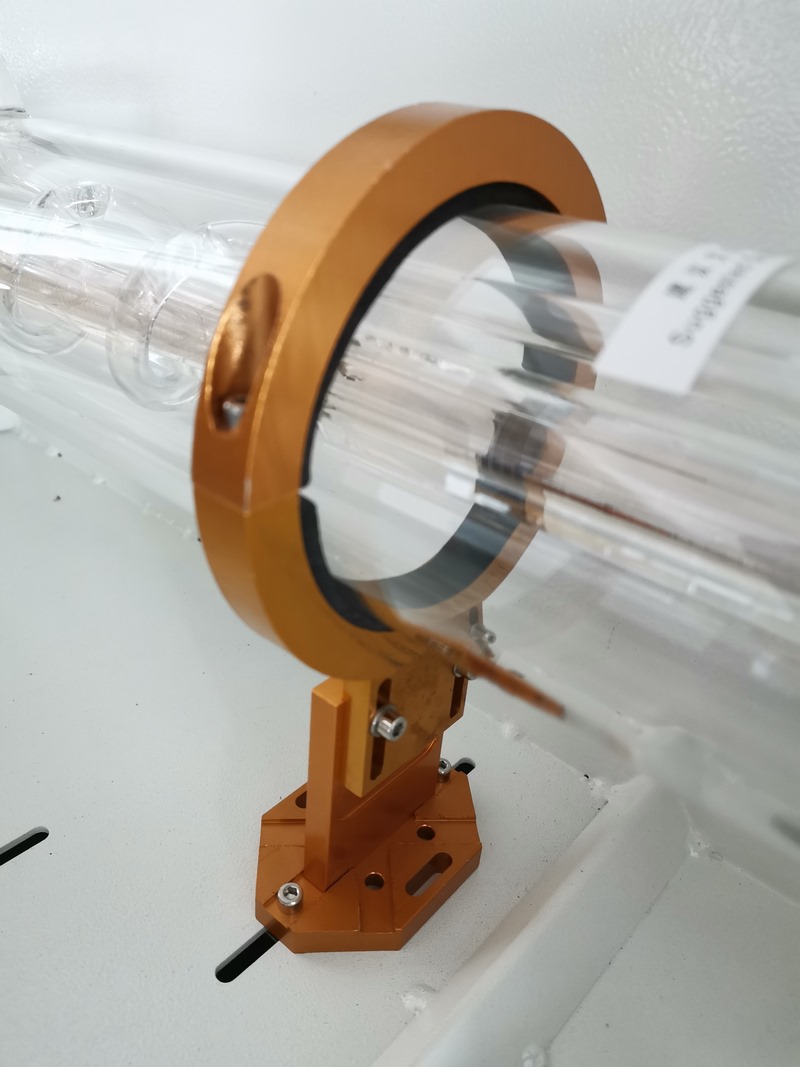

Laser cutting head

High quality laser cutting head, equipped with air blowing control system, suitable for different cutting materials, more convenient to adjust

Laser tube

High power laser tube, stable beam quality, strong durability, and long service life

Control system

Front panel for RDC6445G controller. Emergency stop and ammeter.

Auto feeder

Ensure that the fabric is tidy when transported from the rear to the work table

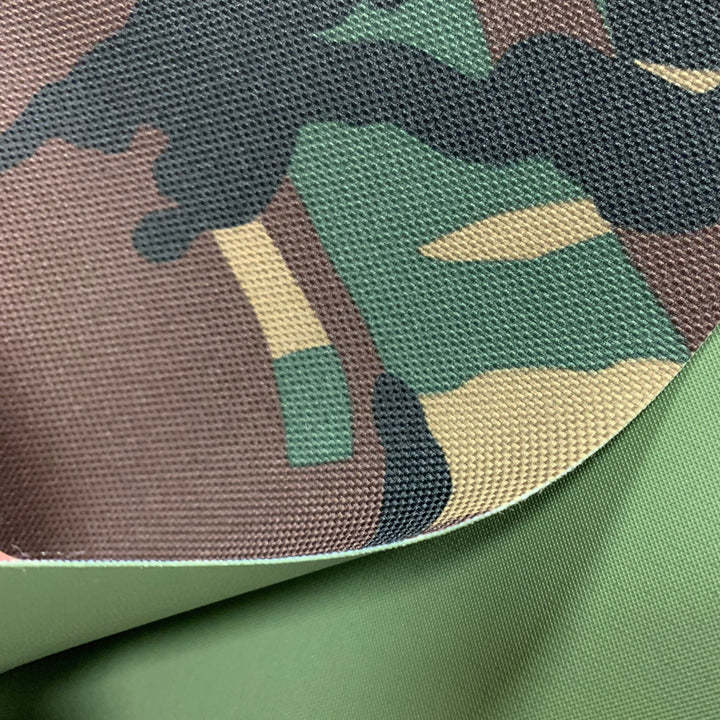

Applicable materials:

Cotton cloth, linen cloth, leather, paper, chemical fiber and other textile and garment fabrics.

Application area:

Sofa release, curtain fabrics, carpets, outdoor tents, coated fabrics, tarpaulins, car interiors, home textiles and various textile products personalized customization, etc. Suitable for cutting various flexible soft materials, hollowing out, etc.

Specially designed for fabric cutting.

BM Laser fabric CO2 laser cutting machine has different types for you to choose: R1610 and R1630, all equipped with auto feeder.

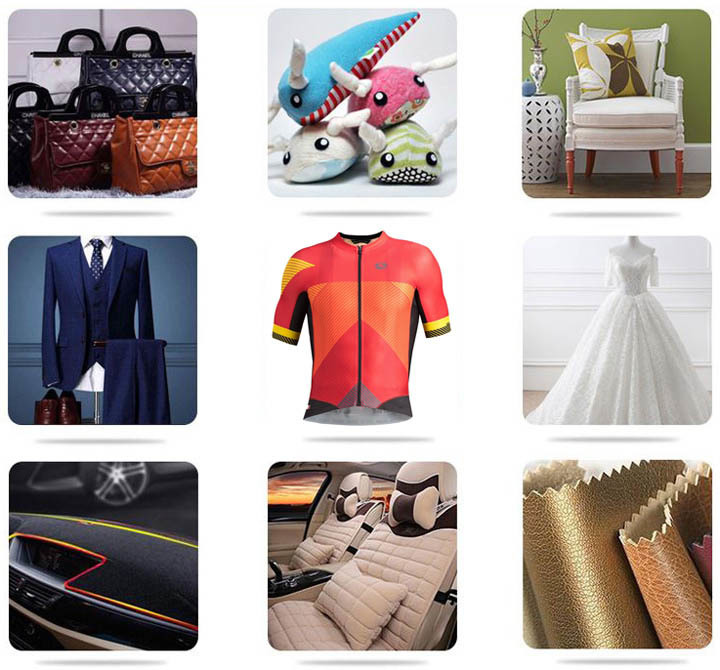

Sample

Application Industry

Technical Parameter

|

Model |

R1610 |

R1630 |

|

With auto feeder |

With auto feeder |

|

|

Laser power |

60W/80W/100W/130W/150W/180W |

|

|

Working area |

1600x1000mm |

1600x3000mm |

|

Laser type |

Sealed CO2 laser tube, wavelength 10.6μm, water-cooled |

|

|

Cooling mode |

Circulating water cooling |

|

|

Engraving speed |

0-1000mm/sec |

|

|

Cutting speed |

0-500mm/sec |

|

|

Repetition accuracy |

≤±0.01mm |

|

|

Transmission type |

Belt transmission |

|

|

Driving system |

Stepper motor |

|

|

Machine table |

Blade table (alternative: honeycomb table) |

|

|

Graphic format supported |

*.plt, *.dst, *.dxf, *.bmp, *.dwg, *.ai, *.las, supporting AutoCAD and CorelDraw |

|

|

Software supported |

CorelDraw, AutoCAD |

|

|

Control system |

RuiDa DSP Off-line control system, laser power 0~100% adjustable |

|

|

Minimum letter size |

Chinese 1.5x1.5mm, English 1.0x1.0mm |

|

|

Working voltage |

220V~240V, 50~60HZ |

|

|

Working condition |

Temperature 0~45 Celsius; Humidity 5%~95% no condensation |

|

|

Control software language |

English/Chinese |

|

Configuration Sheet

Have Questions? Talk to Our Experts!

Related Products