BM Press Brake Mould Factory unveils manufacturing process

Release Time:

Aug 26,2024

BM Press Brake Mould Factory, a leading innovator in the field of industrial tooling, is proud to announce the unveiling of its advanced manufacturing process for bending machine moulds.

With a commitment to precision and quality, BM has optimized each step of the production cycle to ensure superior performance and durability in its moulds.

1. Material Selection: The Foundation of Excellence

The journey begins with the meticulous selection of raw materials. BM sources 42CoMr, the high-grade steel alloys and other premium materials known for their strength and resilience. This careful selection process is crucial for achieving the durability and precision required in high-performance bending machines.

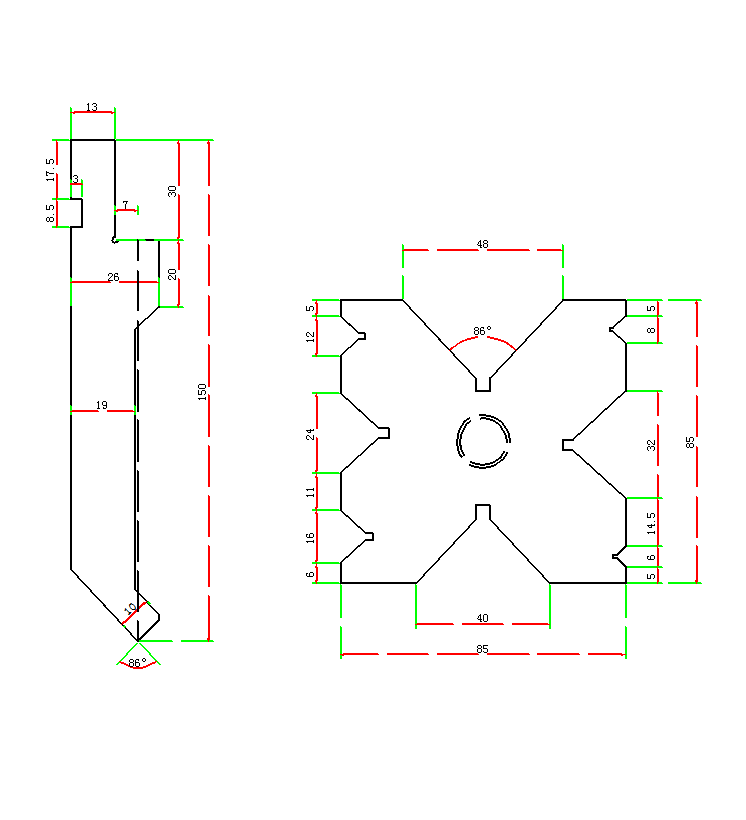

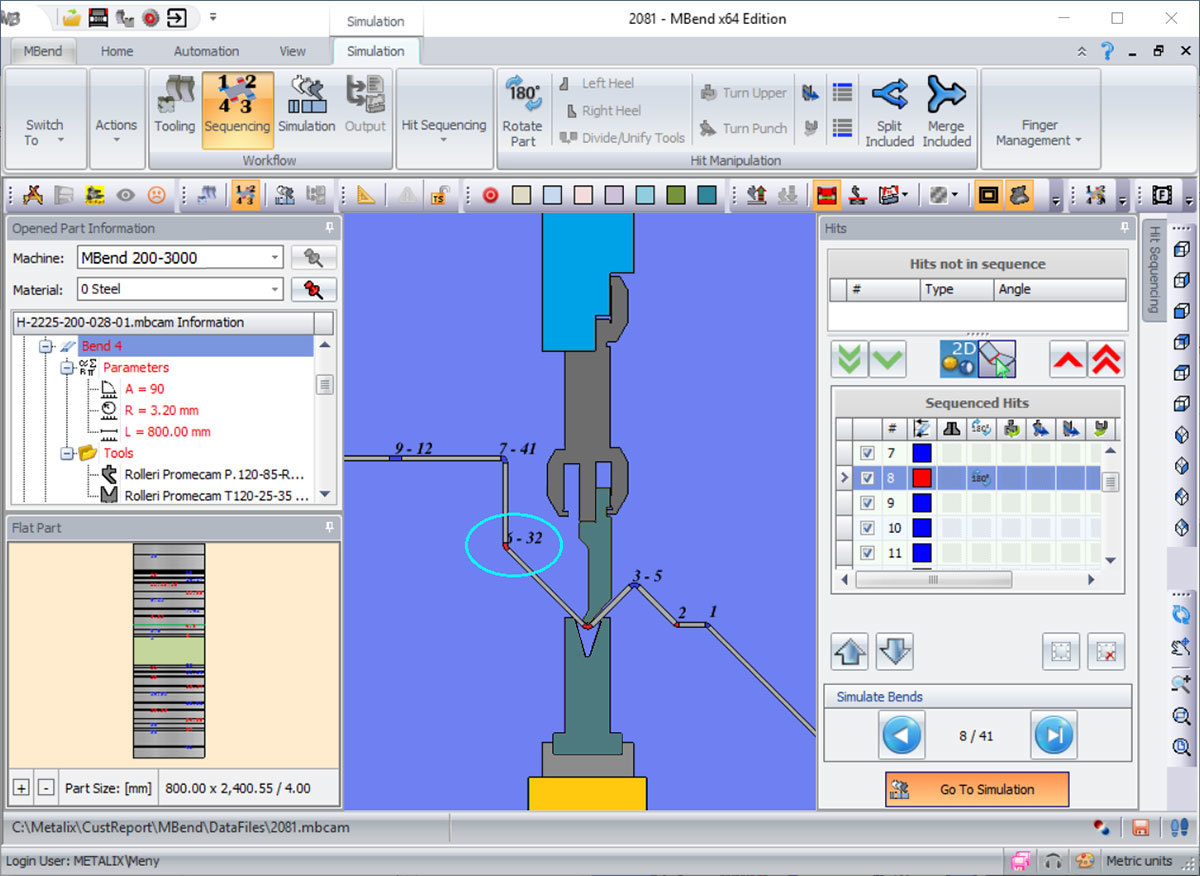

2. Design: Precision Engineering

Once the materials are selected, our experienced engineers design the moulds using cutting-edge CAD software. This design phase involves creating detailed blueprints and simulations to ensure that the moulds meet exact specifications and can withstand the rigors of industrial use.

3. Forging: Shaping the Future

The next step is forging, where raw materials are heated and shaped into the basic form of the moulds. This process enhances the material's strength and prepares it for the subsequent stages of production. Forging is a critical step that defines the initial shape and structure of the mould.

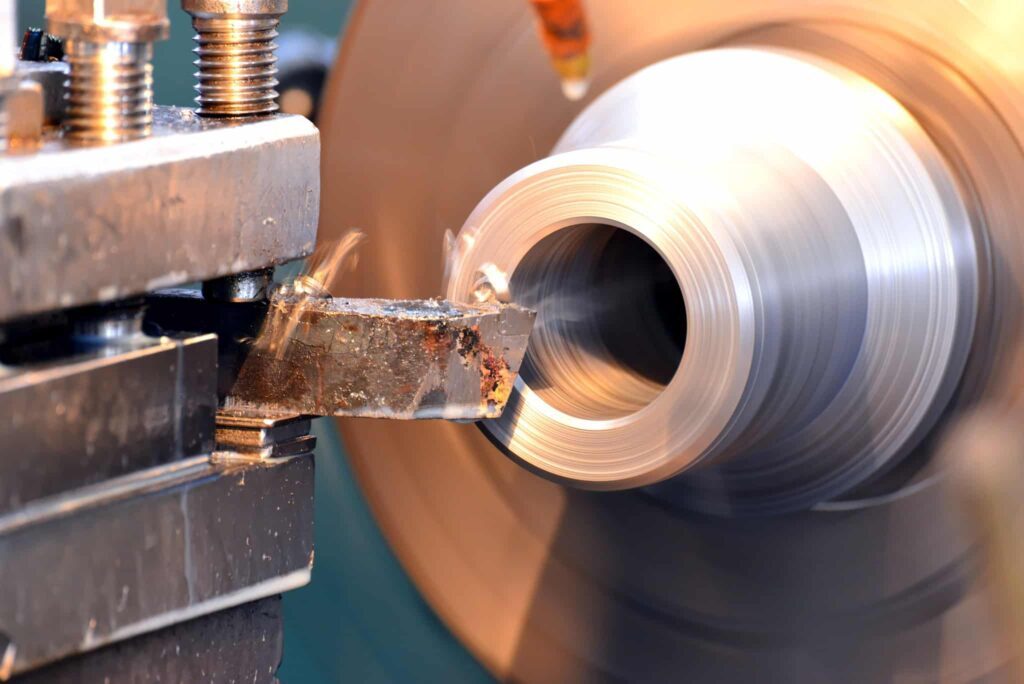

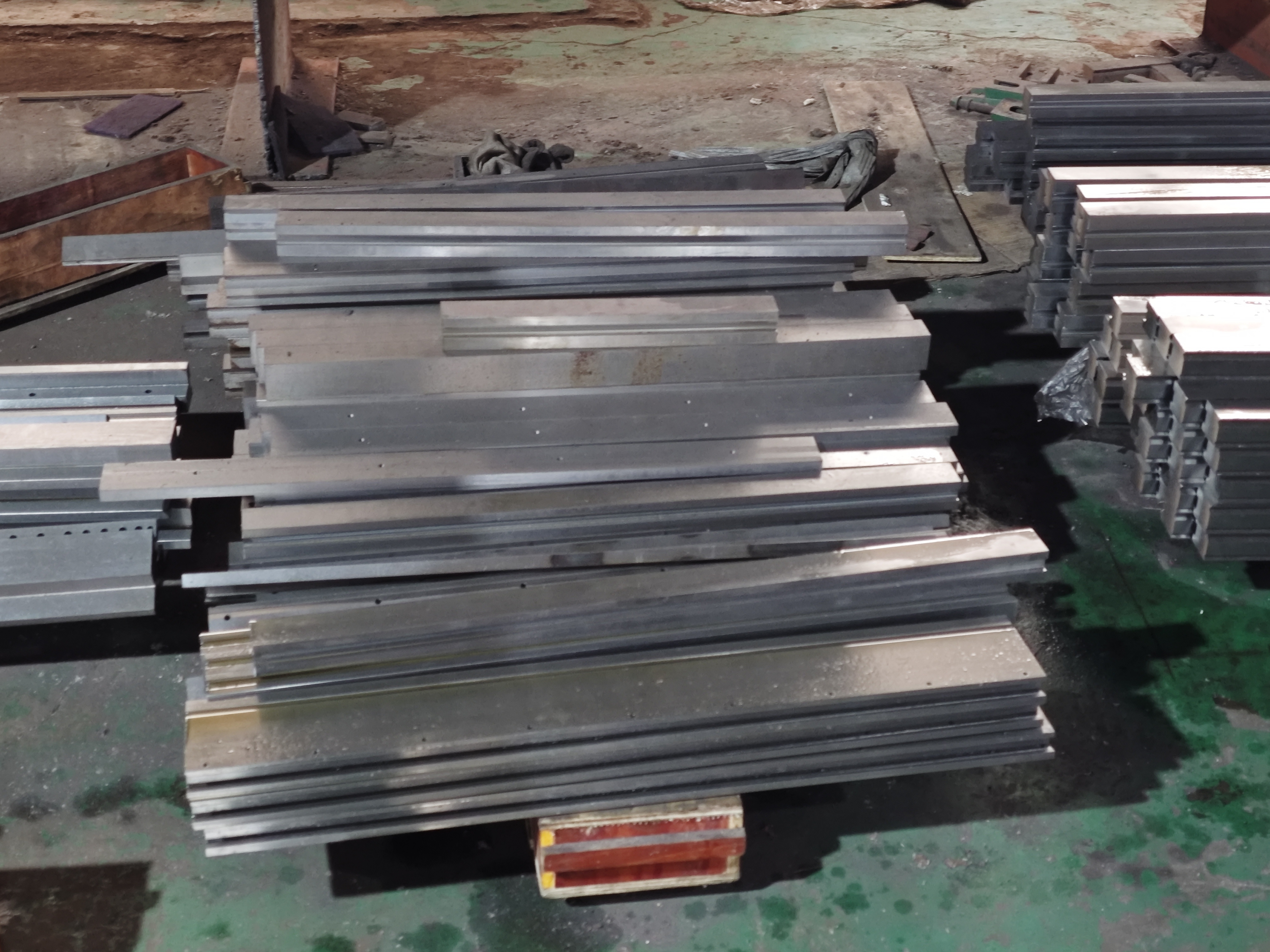

4. Rough Machining: Shaping to Precision

After forging, the moulds undergo rough machining to remove excess material and bring them closer to their final dimensions. This phase involves the use of high-precision machinery to achieve the basic shape and prepare the moulds for more detailed work.

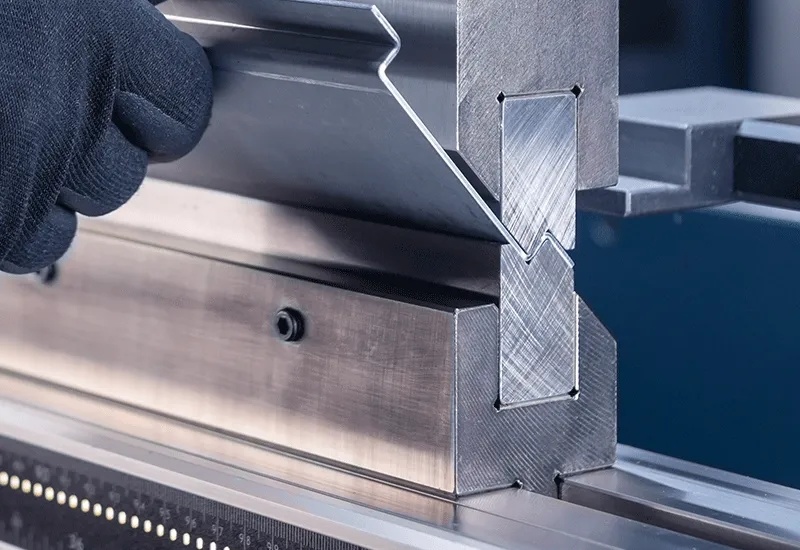

5. Finishing Machining: Achieving Perfection

In the finishing machining phase, the moulds are refined to meet exact specifications. Advanced CNC machines and other precision tools are used to achieve the final dimensions and surface finish, ensuring that the moulds perform flawlessly.

6. Heat Treatment: Enhancing Durability

Heat treatment is employed to improve the mechanical properties of the moulds. This process involves controlled heating and cooling to increase hardness, toughness, and resistance to wear. It is a crucial step for ensuring that the moulds can handle the stresses of repeated use.

7. Polishing: A Flawless Finish

The polishing stage gives the moulds their final, smooth finish. This step not only enhances the appearance of the moulds but also ensures that the surface is free from imperfections that could affect performance.

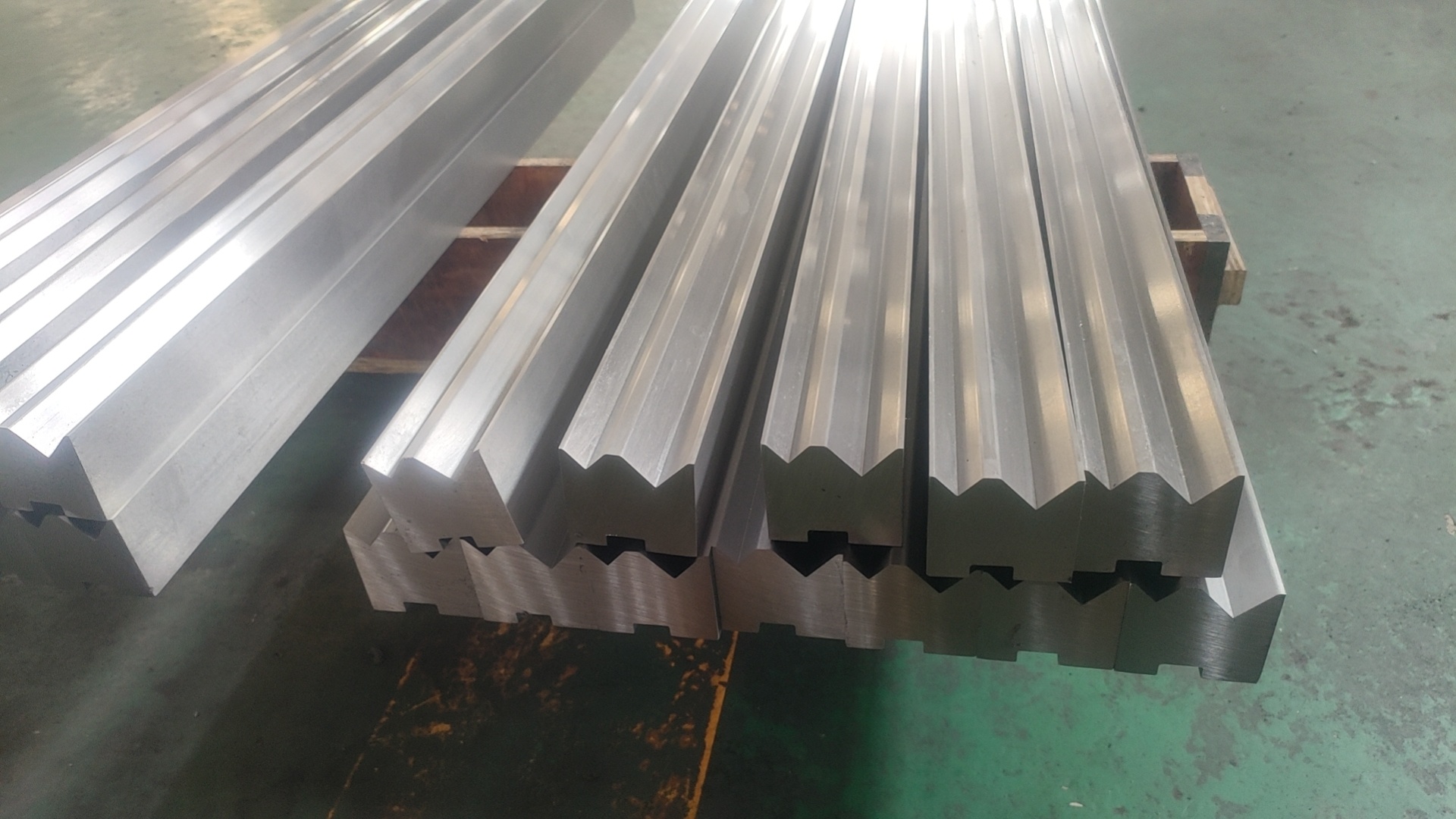

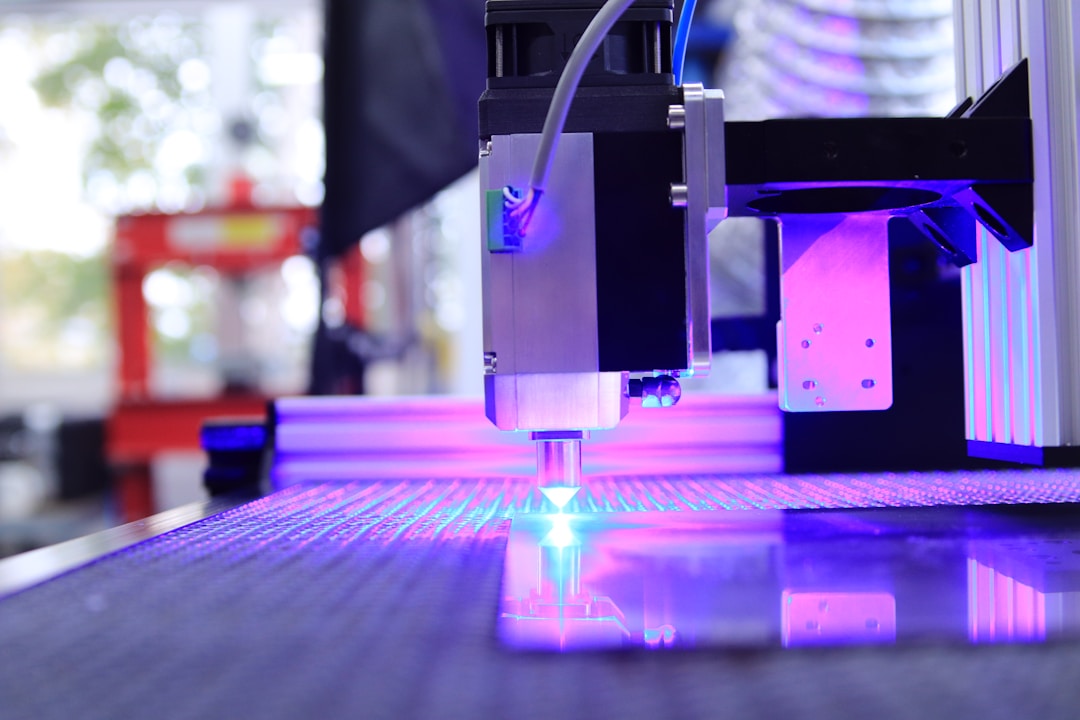

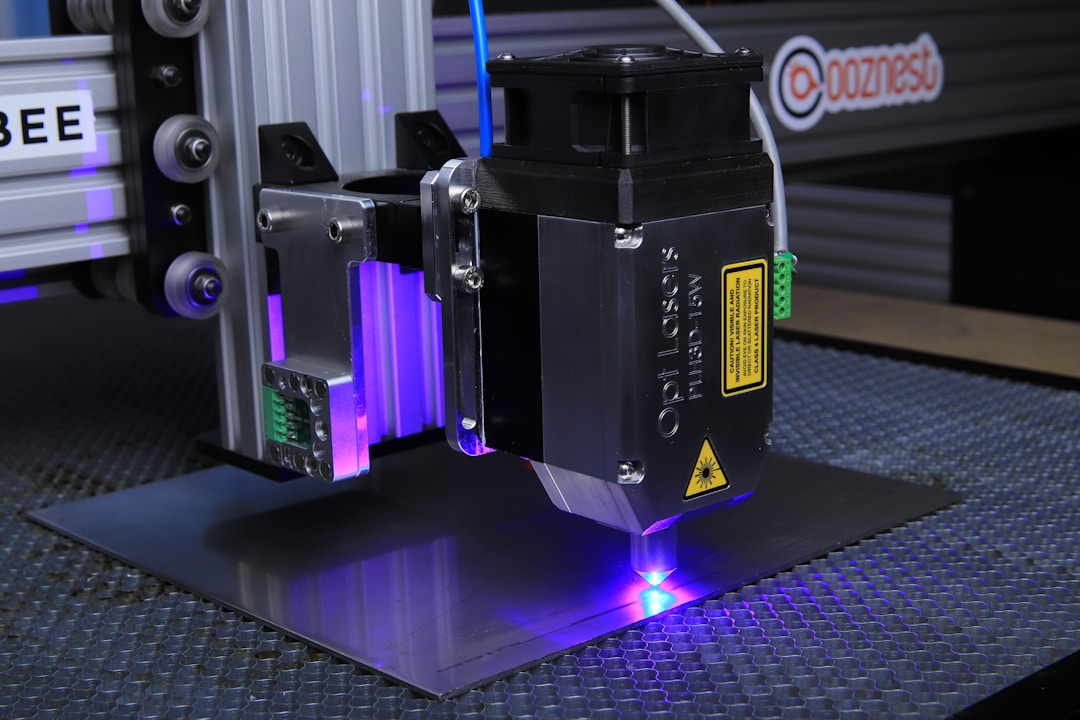

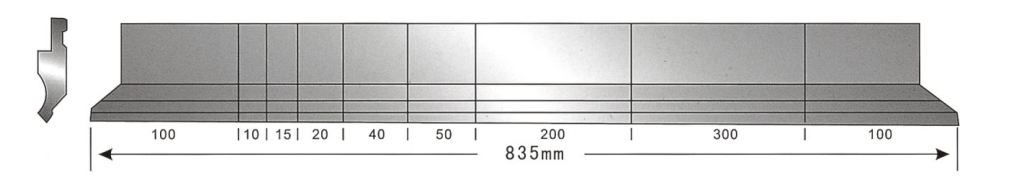

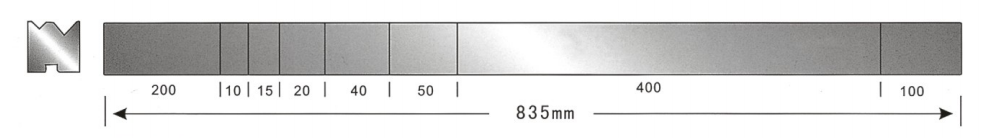

8. Cutting: Precision and Accuracy

Following polishing, the moulds are cut to their final sizes. This step involves precision cutting to ensure that each mould meets the exact specifications required for optimal performance in bending machines.

9. Quality Inspection: Rigorous Testing

Before packaging, each mould undergoes a thorough quality inspection. Our quality control team conducts rigorous tests to verify that the moulds meet our stringent standards for performance and durability. Only moulds that pass this exhaustive inspection are approved for shipment.

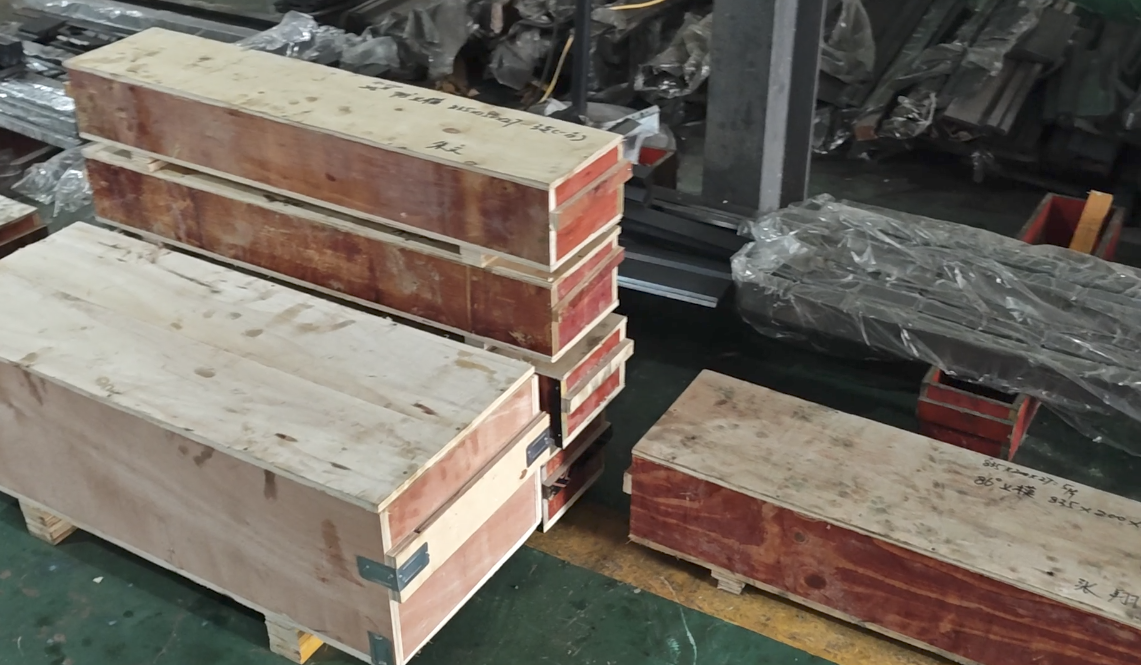

10. Packaging: Safe and Secure

Finally, the moulds are carefully packaged to ensure they reach our customers in perfect condition. Our packaging process is designed to protect the moulds during transit and provide secure delivery to clients worldwide.

BM Press Brake Mould Factory is dedicated to providing industry-leading moulds through a comprehensive and meticulous manufacturing process. By focusing on every detail, from material selection to final inspection, we ensure that our products deliver exceptional performance and reliability.

For more information about BM Bending Machine Mould Factory and our range of high-quality moulds, please visit our website or contact our sales team.

Contact:

Email: info@brm-laser.com

Website: www.bmeurotech.com

About BM Bending Machine Factory:

BM Bending Machine Factory is a premier manufacturer of high-quality bending machine and moulds. With a commitment to innovation and excellence, we provide durable and precision-engineered moulds that meet the highest industry standards. Our manufacturing processes ensure that every mould delivers superior performance and reliability.

Language

Language