Enhance Your Production Efficiency with Our Latest Press Brake Tools

Release Time:

Aug 21,2024

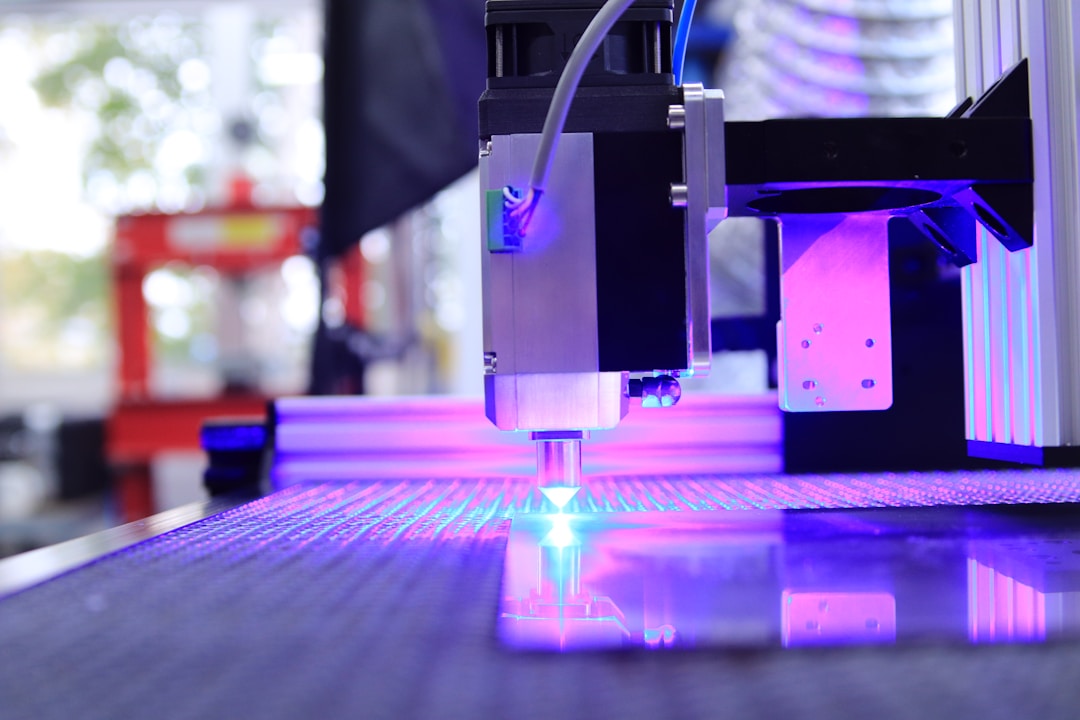

In the world of precision manufacturing and high-efficiency production, the quality of tooling is crucial for achieving optimal product quality and operational efficiency.

Today, we are thrilled to announce the launch of our latest Press Brake tool series, crafted with industry-leading standards in material selection, hardness, and wear resistance.

Material Selection: Ensuring Superior Performance

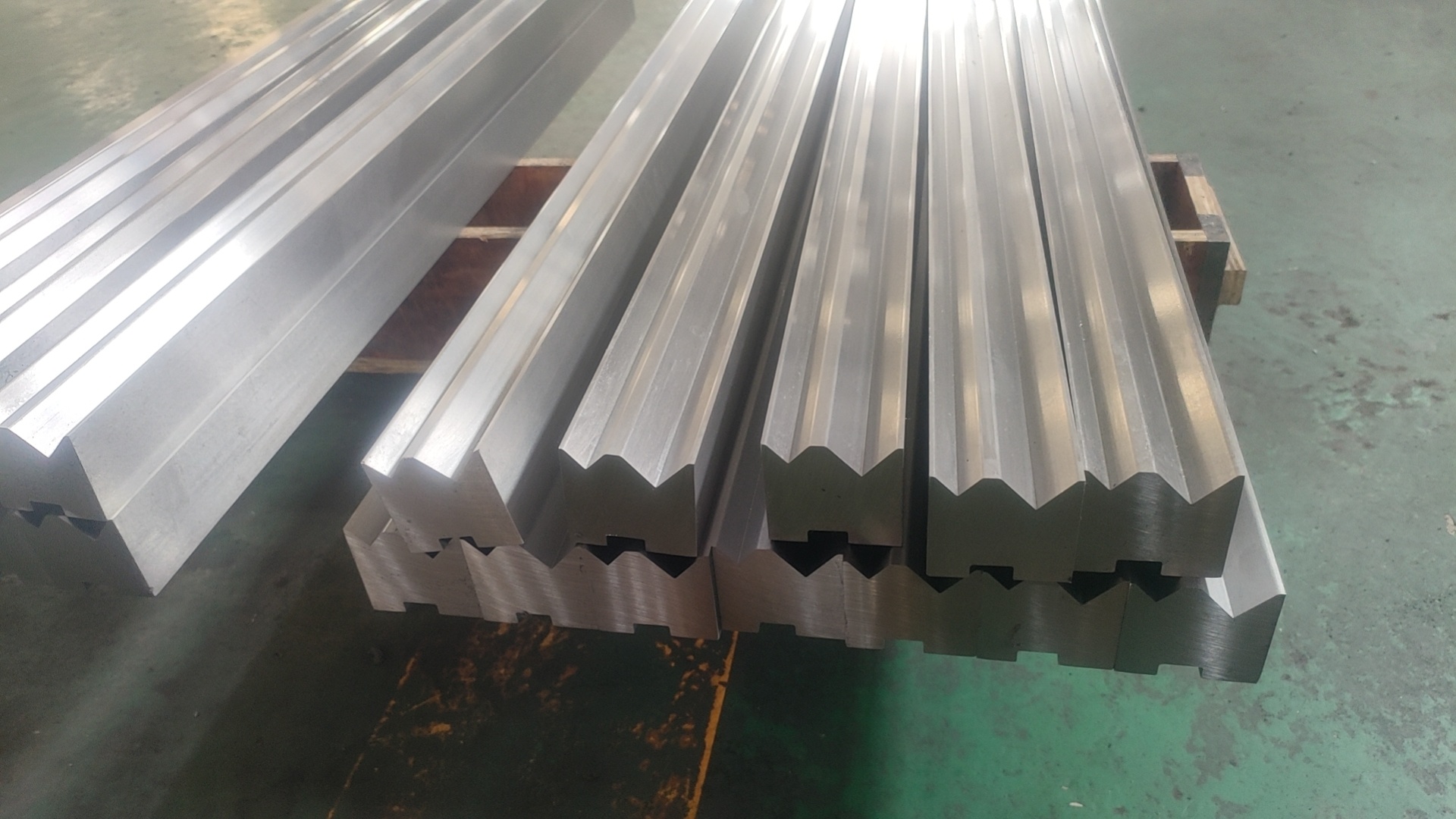

At the heart of our new Press Brake tools is our commitment to using premium raw materials. Our tools are manufactured from high-grade 42CrMo steel, renowned for its excellent mechanical properties and long-term stability. This steel is selected for its superior strength and durability, ensuring that our tools maintain their integrity under high stress and demanding conditions. The choice of 42CrMo steel ensures that our tools exhibit minimal deformation and extended service life, even in the most challenging manufacturing environments.

To summarize, 42CrMo is a versatile alloy steel, boasting impressive hardenability, machinability, and weldability. Its surface hardness, mainly dictated by the applied heat treatment, plays a pivotal role in defining its overall performance. Therefore, understanding these key attributes is essential in leveraging 42CrMo’s full potential in various applications.

Hardness Treatment: Enhancing Precision

To achieve unmatched precision and durability, our Press Brake tools undergo advanced hardness treatment. Our state-of-the-art heat treatment process ensures that the tools achieve a hardness level of HRC 50-55. This high hardness not only extends the lifespan of the tools but also enhances their precision during metal forming processes. Whether handling intricate bends or large-scale production runs, our tools deliver consistent performance and accuracy, meeting the highest industry standards.

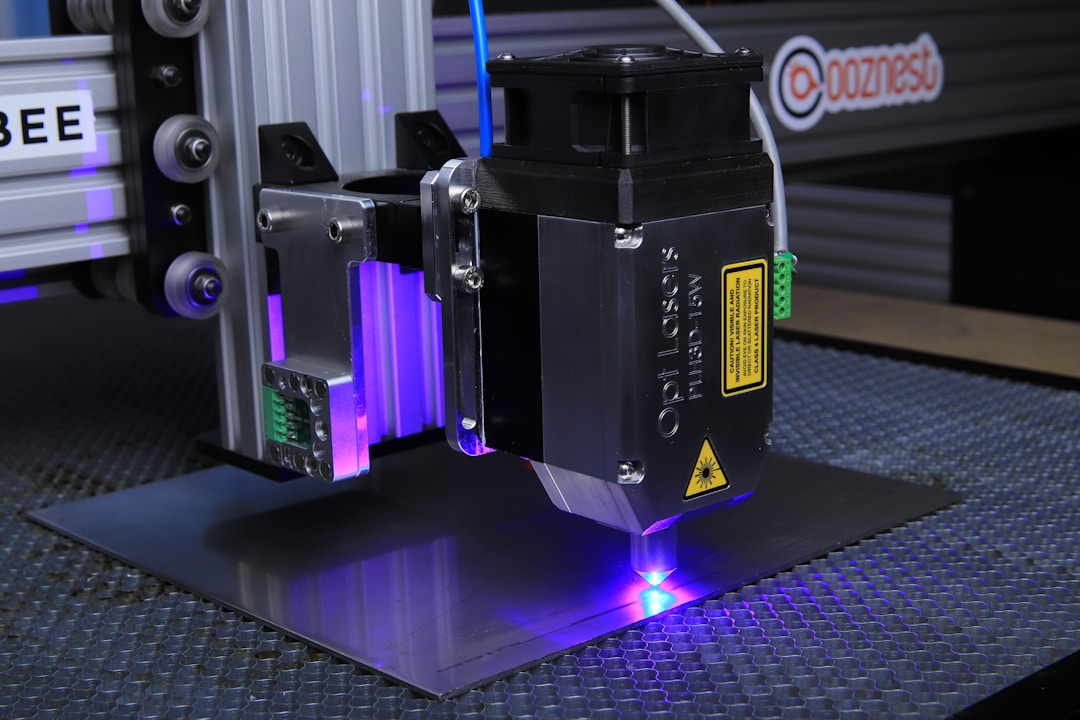

Wear Resistance: Ensuring Long-Term Efficiency

Wear resistance is a critical factor in tool performance, particularly in high-frequency and high-pressure applications. Our Press Brake tools feature advanced surface treatments, including nitriding and chrome plating, to enhance their wear resistance and corrosion resistance. These treatments significantly increase the surface hardness of the tools, reducing the frequency of maintenance and minimizing downtime. As a result, our tools help improve overall production efficiency and reliability.

Summary

Our new Press Brake tool series, with its superior material selection, precise hardness treatment, and exceptional wear resistance, is designed to elevate your manufacturing processes. We are dedicated to providing cutting-edge tooling solutions that help our clients achieve higher efficiency and precision in their production goals.

For more information about our Press Brake tools or to consult with our expert team, please visit our website or contact us directly.

Contact Information:

Email: info@brm-laser.com

Website: www.bmeurotech.com

About BM

BM is committed to delivering innovative press brakes and tool solutions to the manufacturing industry. With 23+ years experience and advanced technology, we continually push the boundaries of industry standards, helping our clients achieve success in a competitive market.

Language

Language