Upgrade on HE Series CNC Hydraulic-Electric Servo Press Brake

Release Time:

Apr 30,2025

Introducing the Next Generation of Precision: HE Series CNC Hydraulic-Electric Servo Press Brake

At the cutting edge of sheet metal fabrication, precision, customization, and efficiency define the difference between a good product and an exceptional one. That’s why we are proud to unveil our newly upgraded CNC Hydraulic-Electric Servo Press Brake—HE Series—with the debut model HE1703 (170 tons, 3.2 meters), setting a new benchmark in performance and reliability for the modern fabrication shop.

This new model is the result of deep engineering refinement, incorporating customer feedback, and advancing the essential values of strength, accuracy, and user-focused design.

Performance Powered by Intelligence

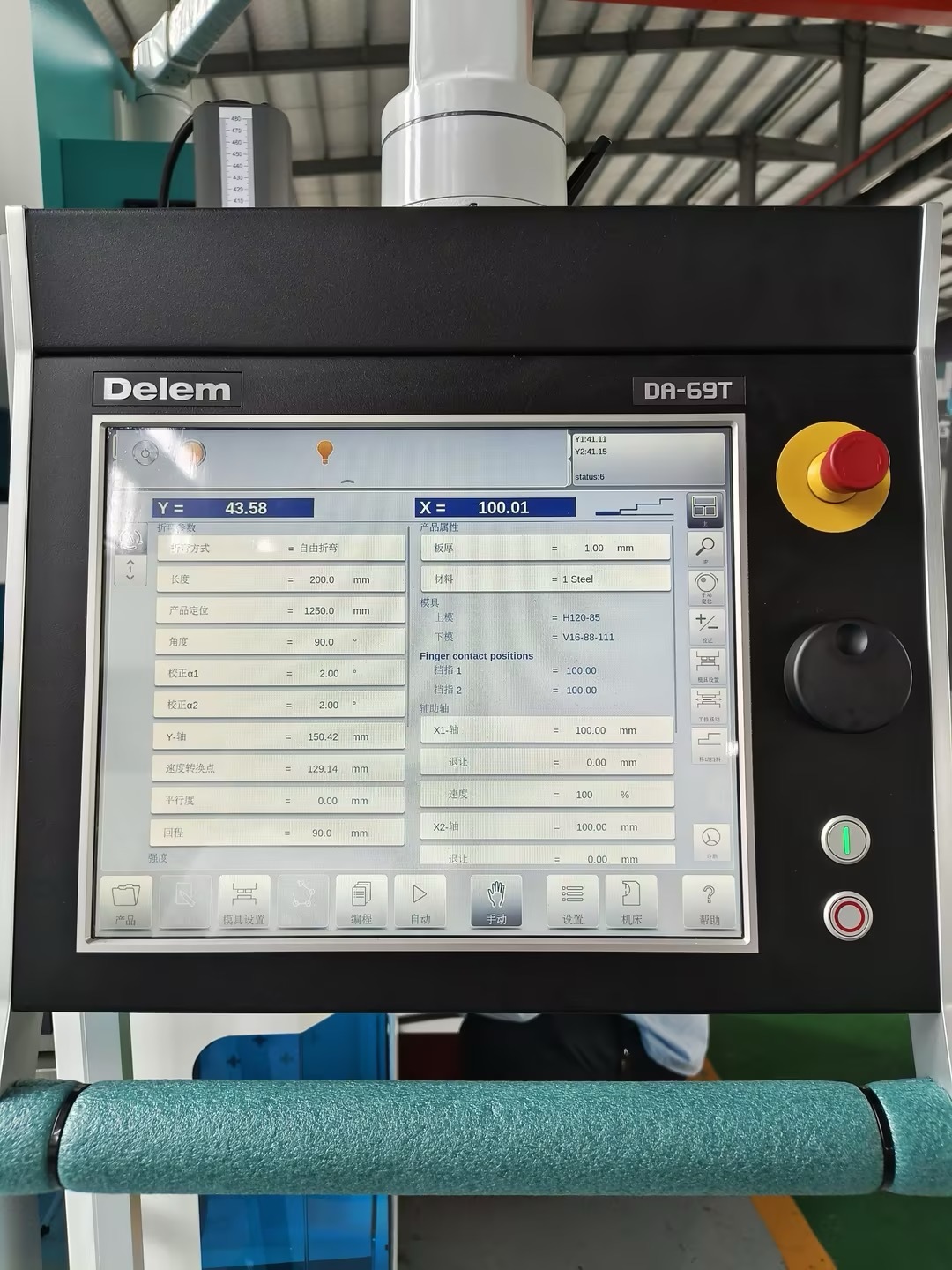

The HE1703 press brake operates with a high-power 18kW servo motor, providing precise and responsive motion control. It's complemented by six auxiliary motors (0.75kW each) for the X, R, and Z axes, ensuring seamless multi-axis operation in an 8+1 axis configuration. This enables complex bending tasks to be executed with ease and minimal setup time.

The brain of the machine—the CNC controller—is the DELEM DA69T, known for its user-friendly interface and robust 3D visualization capabilities. In upcoming models, this will be further upgraded to the new DA69S system, which brings even more responsive control and process optimization features to the table.

Built Like a Fortress, Engineered for Accuracy

The HE1703 press brake is built with uncompromising rigidity. The machine frame walls, slider, and bottom die base are constructed with 70,70,90 cm thick steel sections, ensuring minimal deflection under load. This solid foundation significantly enhances long-term accuracy and repeatability. Total weight can be exceed to 10Tons.

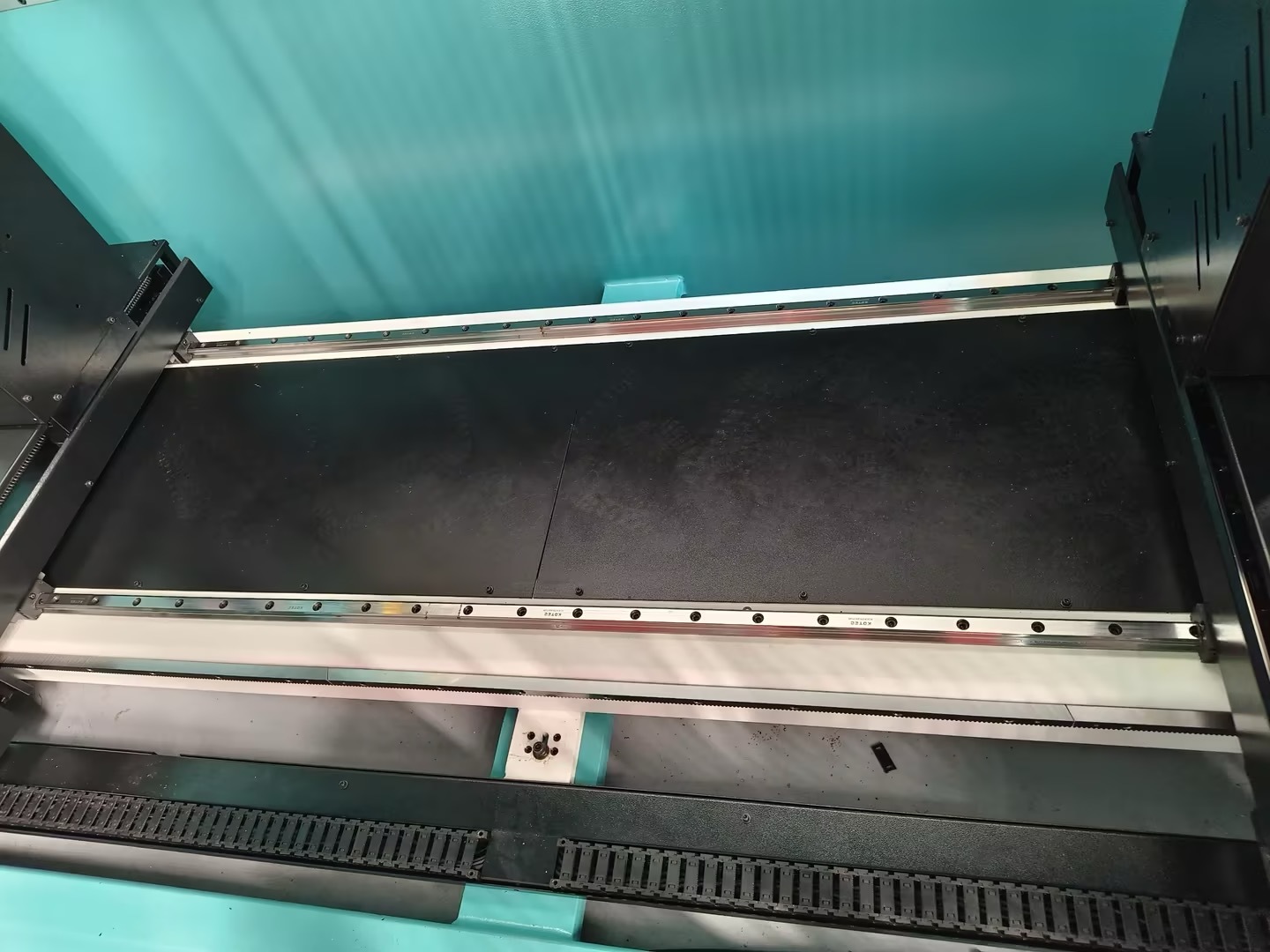

Equipped with a CNC mechanical crowning compensation device, the machine actively adjusts to prevent deflection during bending, maintaining consistent angles across the entire length of the workpiece. This is essential for long and heavy sheet metal applications.

Customization at Its Core

Understanding that every workshop is different, we offer fully customizable bending tools. Each upper punch, lower 4-V die, and die base is tailored to meet your production requirements. Whether you're dealing with delicate stainless steel or heavy-duty carbon plate, our tooling solutions ensure maximum bending precision and longer tool life.

The press brake also comes with the latest dual-sided quick clamping system, making tool changeovers faster, easier, and safer.

High-End Components, Down to Every Detail

What sets the HE Series apart is its uncompromising approach to component selection. Each part of the machine reflects our commitment to quality:

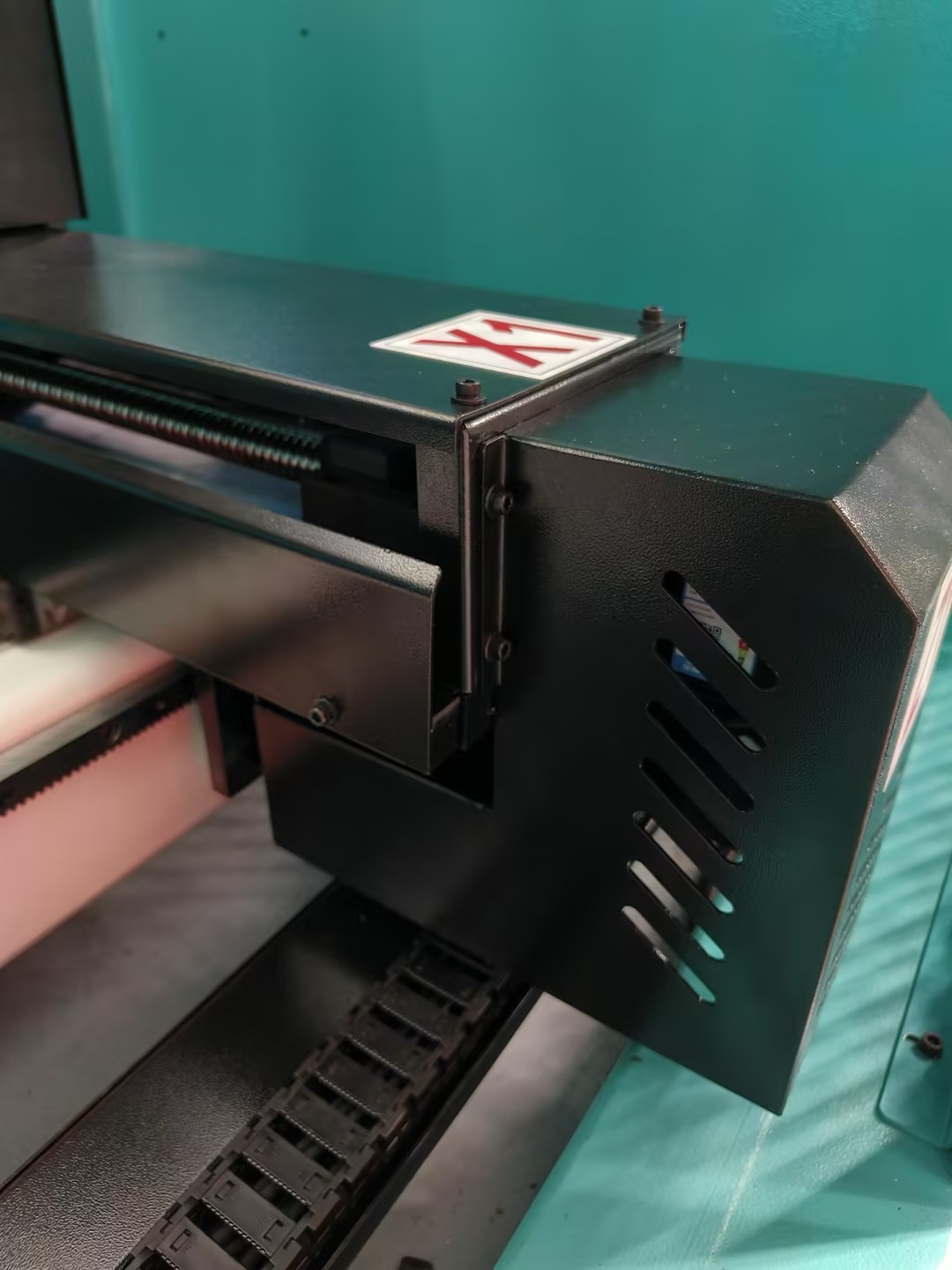

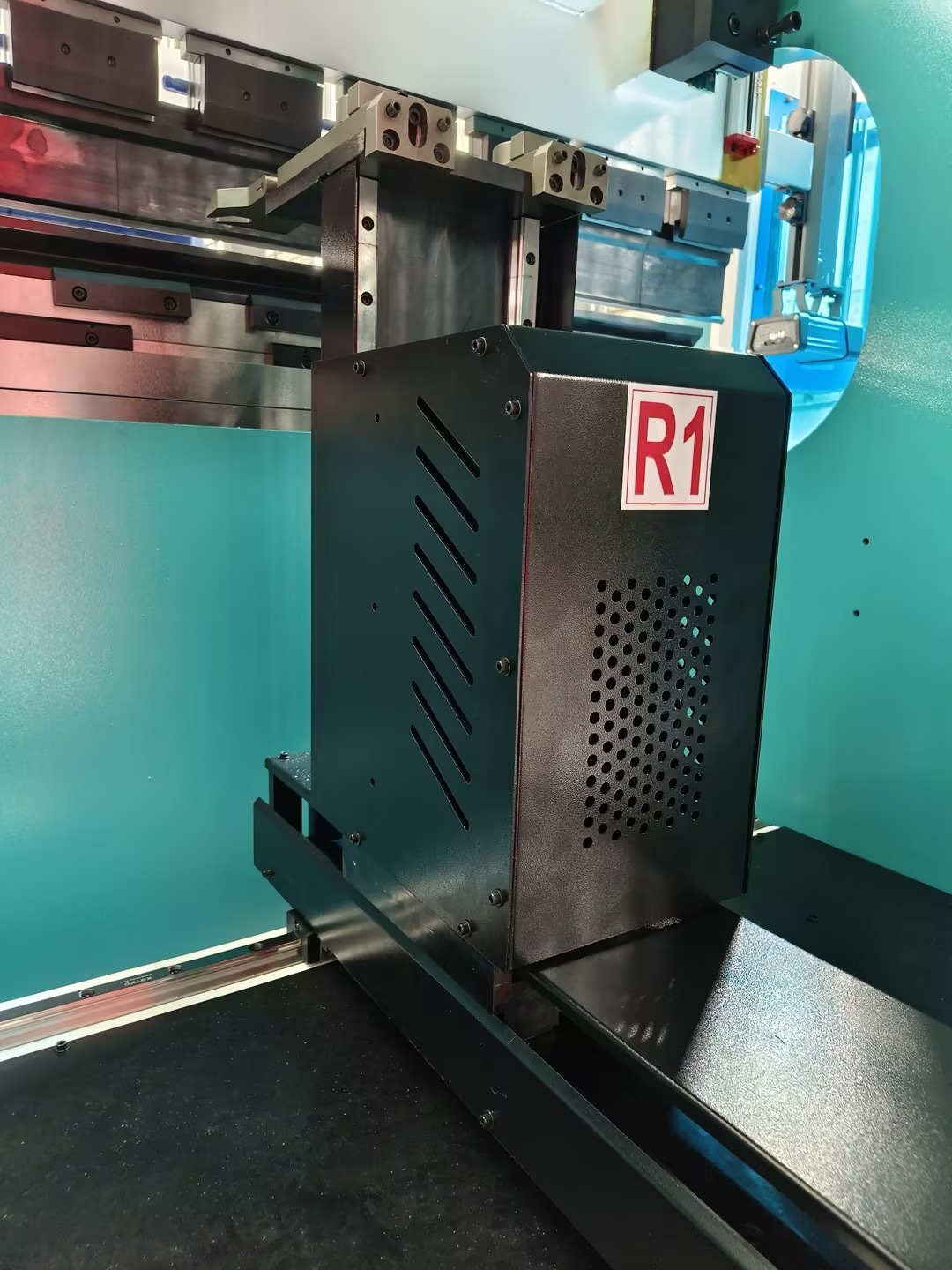

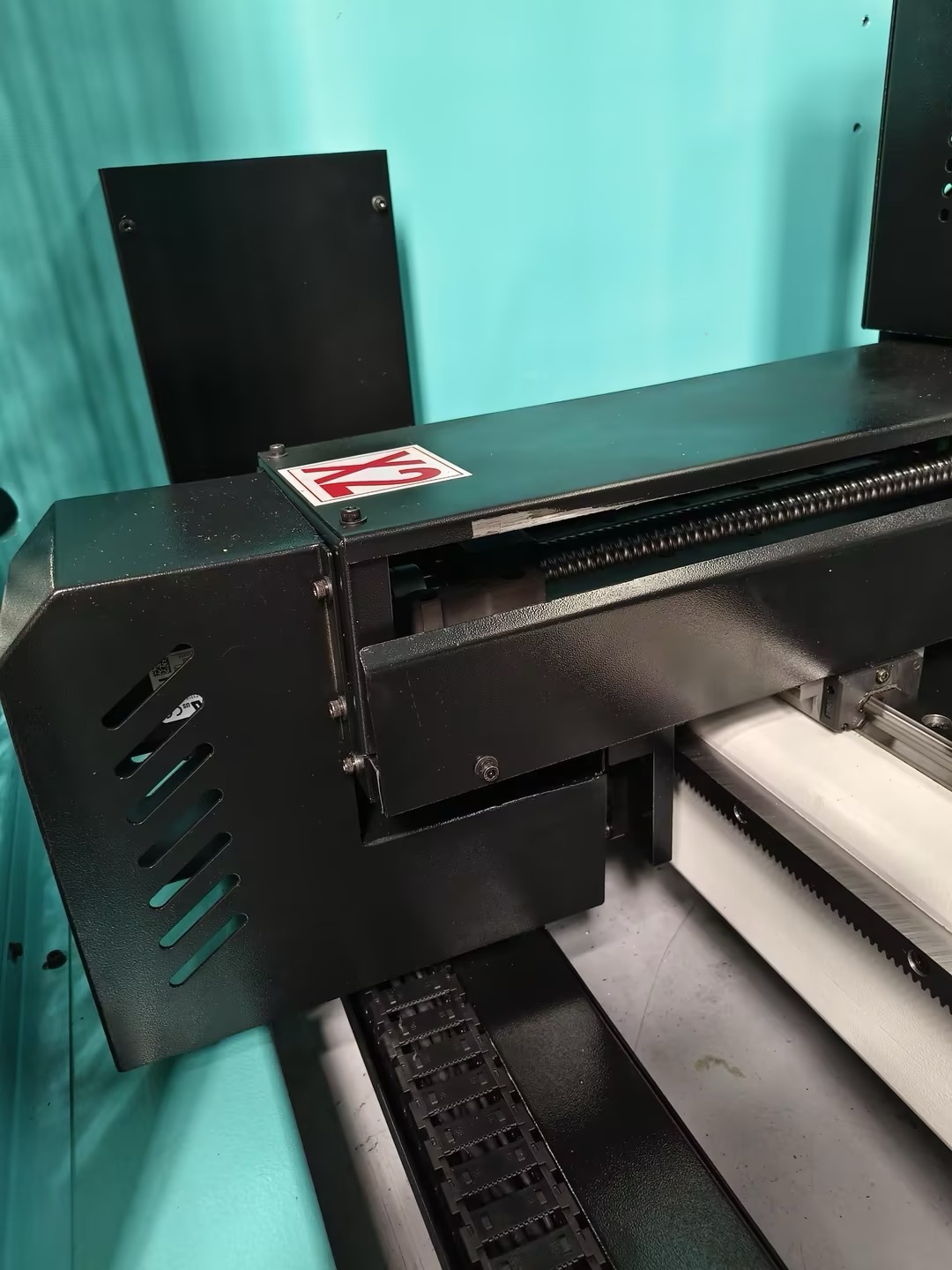

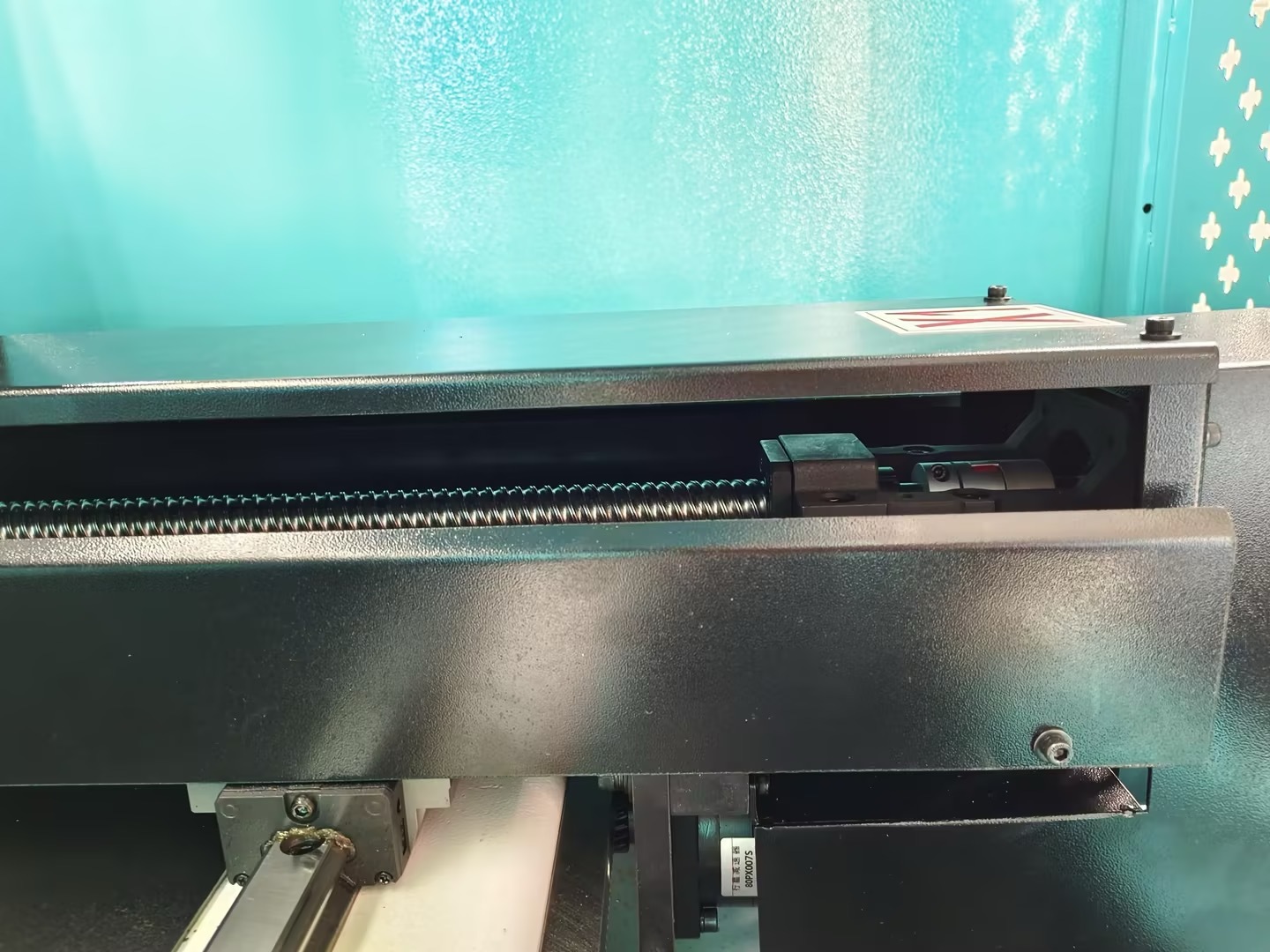

Backgauge with dual-linear guides: Delivers precise positioning for repeatable accuracy.

Front sheet support with linear movement: Assists in handling larger sheets with ease, reducing operator fatigue and error.

High-response servo valves and grating rulers: Ensure precise hydraulic control and positional accuracy during bending cycles.

Ball screws, bearings, and a robust electric system: Chosen for durability and high-efficiency operation.

Hydraulic oil tank, oil pump, and oil cylinders: Sourced from trusted suppliers to ensure stable, long-life hydraulic performance.

Safety Meets Modern Design

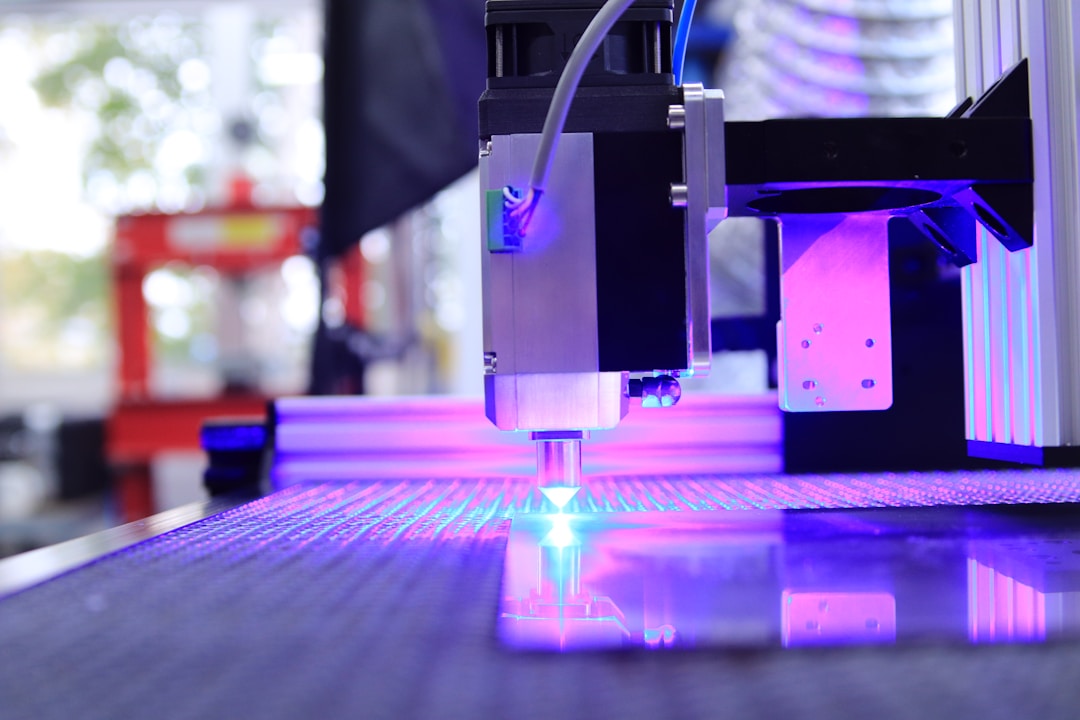

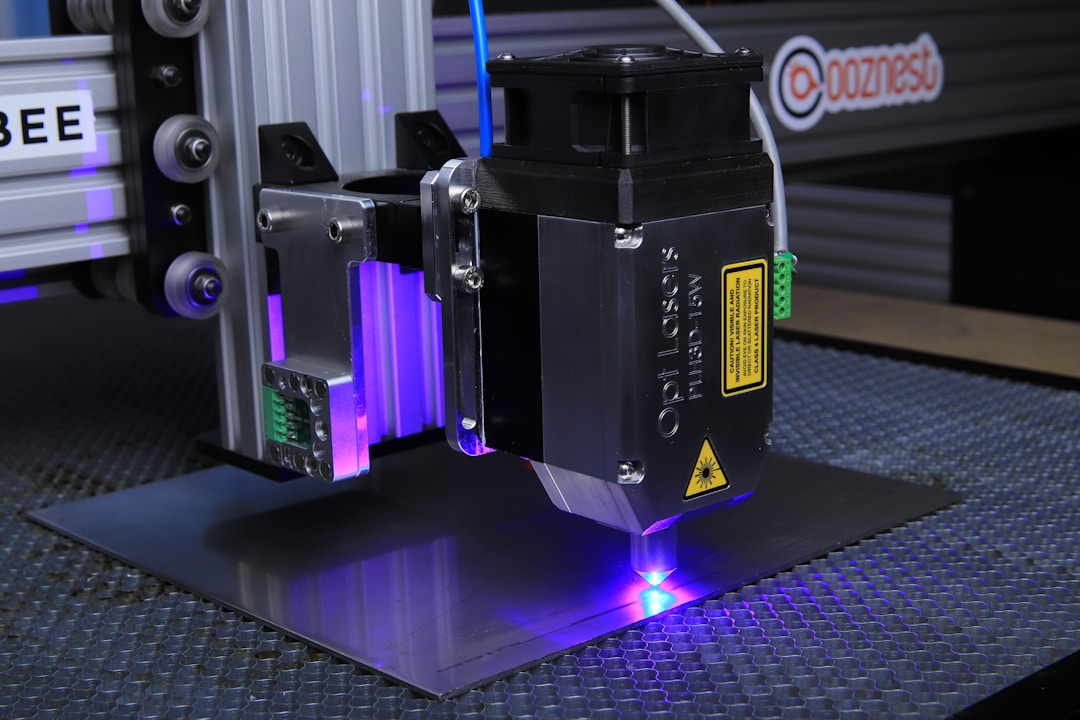

Your safety is our priority. The HE1703 comes with a laser safety device that monitors operator movement and stops the machine instantly if any obstruction is detected. A back safety door adds another layer of protection, ensuring safe maintenance and operation.

The exterior of the machine features a modern LED lighting strip, not only enhancing visibility during operation but also adding a sleek, professional look to your workshop. The blend of function and style shows that the HE Series isn’t just built to work hard—it’s built to impress.

Ideal for Diverse Applications

Whether you're producing parts for the automotive industry, aerospace, home appliances, or custom job shop work, the HE1703 is built to handle it all. Its combination of power, precision, and adaptability makes it the ideal solution for today’s fast-paced, high-expectation metalworking environments.

Why Choose the HE Series?

Advanced Technology: DELEM controller, servo motors, and CNC crowning for unparalleled control.

Durability: A reinforced structure ensures minimal deflection and long-term accuracy.

Customization: Tools and configurations built around your needs.

Efficiency: 8+1 axis with automatic motor-driven adjustments reduces setup time.

Safety: Top-level protection features including laser safety and enclosed back door.

Design: A blend of industrial power and modern visual appeal.

Conclusion

The HE Series HE1703 isn’t just an upgraded machine—it’s a complete bending solution designed to raise your production capabilities. With world-class components, unmatched rigidity, and intelligent control, this press brake gives you the confidence to take on more complex jobs with higher efficiency.

Whether you're upgrading from an older model or expanding your production line, the HE1703 offers everything you need in a modern press brake—power, precision, safety, and speed.

Contact us today to learn more about how the HE Series can elevate your fabrication capabilities.

Email: Info@brm-laser.com

WhatsApp: 86-18867408079

Language

Language