Punching Tooling Solutions for Modern Sheet Metal Processing

Release Time:

Sep 05,2025

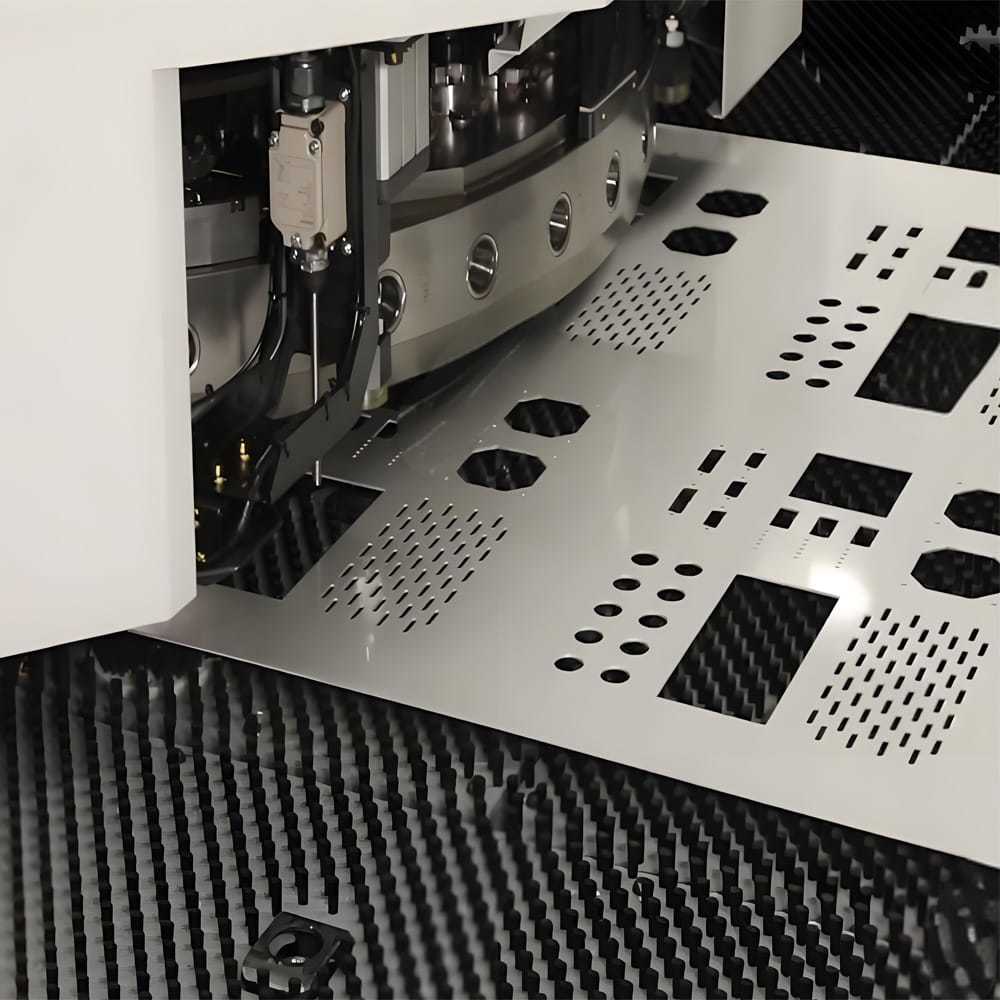

Understanding CNC Turret Punching Machines: Structure, Working Principle, and Applications

In the field of sheet metal fabrication, punching tooling plays a critical role in ensuring accuracy, efficiency, and product quality. At BM, we have been specializing in turret punch press tooling for over 30 years, offering reliable solutions to customers worldwide.

What is Punching Tooling?

Punching tooling consists of punches and dies that work together inside a turret punch press to create holes, slots, louvers, embossments, and various shapes on sheet metal. The punch pushes into the die, shearing the sheet metal precisely according to the tool geometry.

Key Components of a CNC Turret Punching Machine

Upper and Lower Turrets

The heart of the system. These rotating tool holders house both punches and dies, and their positioning is fully controlled by the CNC program.

Clamps

They secure the sheet metal and precisely move it into the punching area, ensuring accuracy in every stroke.

Striker (Ram)

The driving force of the machine. Powered either by hydraulic or servo-electric systems, the striker delivers the downward motion that drives the punch into the die.

Turret Key

Maintains angular alignment of tools, ensuring accurate positioning during rotational movements.

Die Holder & Die

The die holder is mounted in the lower turret and secures the die in place. The die itself defines the shape and dimension of the punched hole—making it one of the most critical elements of the process.

Lifter

This mechanism lifts the punch after each stroke, allowing smooth repositioning of the sheet metal for the next operation.

BM Tooling Product Range

We manufacture tooling compatible with the four major turret systems:

Thick Turret Series (widely used in international turret presses)

Thin Turret Series

TRUMPF Series

Murata Series

Our tooling includes:

✔ Punches (round, square, oblong, cluster, forming tools, etc.)

✔ Dies (standard and special designs)

✔ Strippers and accessories

✔ Custom-made solutions for special applications

Why Choose BM Tooling?

30+ production experience – trustworthy partnership and stable production volume each year.

High precision manufacturing – ensuring tight tolerances and long tool life.

Premium materials & heat treatment – excellent hardness, toughness, and wear resistance.

Customization service – tailored tooling for unique applications.

Global compatibility – fully compatible with world-class brands such as TRUMPF, Amada, Murata, and more.

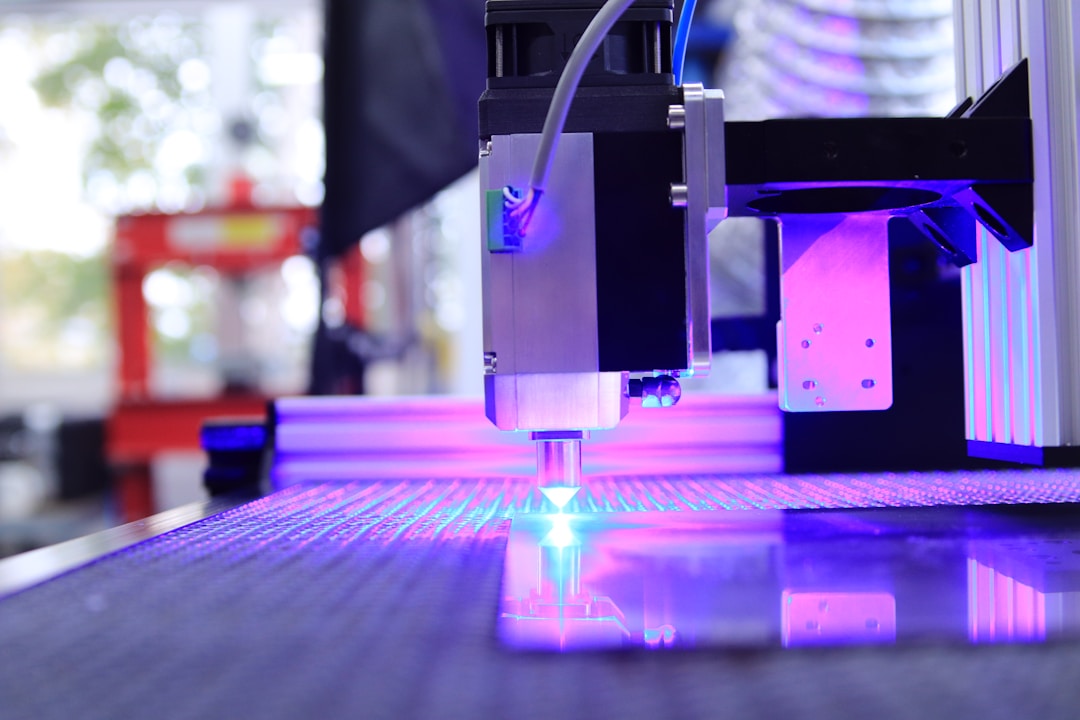

How Does a CNC Turret Punching Machine Work?

In simple terms, the process is a combination of precision motion control and powerful punching force:

The CNC system moves the sheet metal in both X and Y directions according to programmed instructions.

The striker drives the punch downward with hydraulic or servo-electric force.

The punch penetrates the material, and the die defines the exact geometry of the hole or feature.

The lifter retracts the punch, and the cycle repeats until the part is completed.

This automated process allows high-speed, consistent, and repeatable production

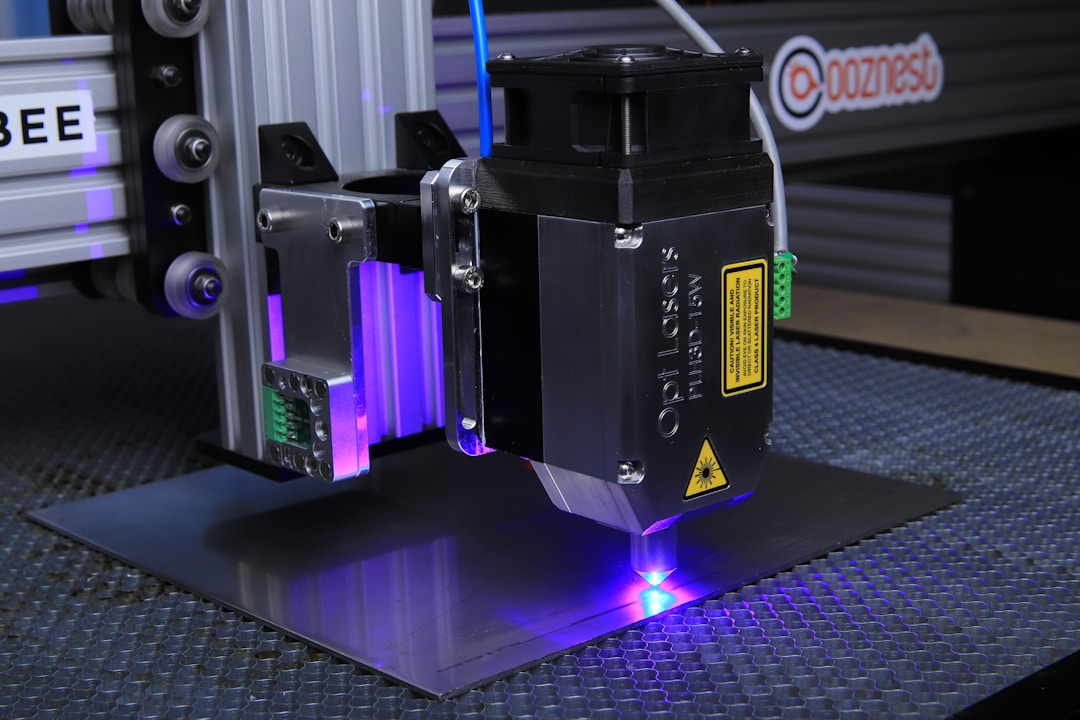

Advantages of CNC Turret Punching Machines

High efficiency – Ideal for medium to large production volumes.

Cost-effective – Lower tooling and operating costs compared to some alternative methods.

Versatility – Capable of producing holes, slots, louvers, embossments, and even forming operations.

Speed – Faster than laser cutting for many repetitive hole patterns.

Precision & repeatability – Ensures uniform shapes across all parts.

Turret punch presses are the preferred solution for repetitive punching patterns where identical shapes are required across a workpiece. They excel in applications that demand both accuracy and productivity, outperforming traditional stamping methods while offering greater flexibility in design changes.

Applications

BM punching tools are widely applied in industries such as:

Electrical cabinets, HVAC systems, Automotive components, Furniture and architectural panels, General sheet metal processing.

Welcome to BM Punching Tools

Whether you need standard punches and dies or custom-designed solutions, we ensure top-quality products that help improve your production efficiency and sheet metal performance.

🌐 www.bmeurotech.com

📧 info@brm-laser.com

Language

Language